Our hands-on engineers are always on hand to fix your problems.

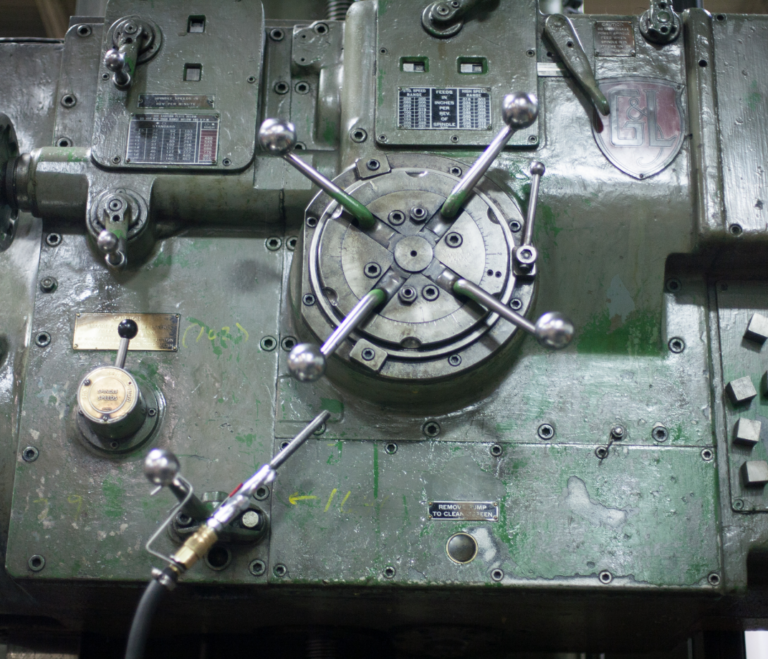

Bonnot machines are built to last. Many are still running after decades of continuous use. But there will always be some parts that need replacing after years of hard work. For high wear, highly abrasive applications, such as chemical catalyst or carbon products, we offer a rebuild program.

As we have a dedicated hands-on approach to building your extruder, one of our vastly experienced engineers will know the inner workings of your machine. This translates into expert support to advise your maintenance and production team on the optimal solution.

When you need us, we react quickly, getting you back up and running as soon as possible. Our field service team will work closely with Bonnot HQ in Ohio to get you the parts you need…stat! We even keep an inventory of your machine’s spare parts on our shelves so we can send them to you in the case of a sudden need for a replacement park.

We offer these services on an ad-hoc basis on in a ‘master services agreement’ relationship, where there is visibility over anticipated wear and need for rebuild and replacement parts. These types of agreements allow us to offer significant discounts on spare parts and are utilized by many major manufactures.

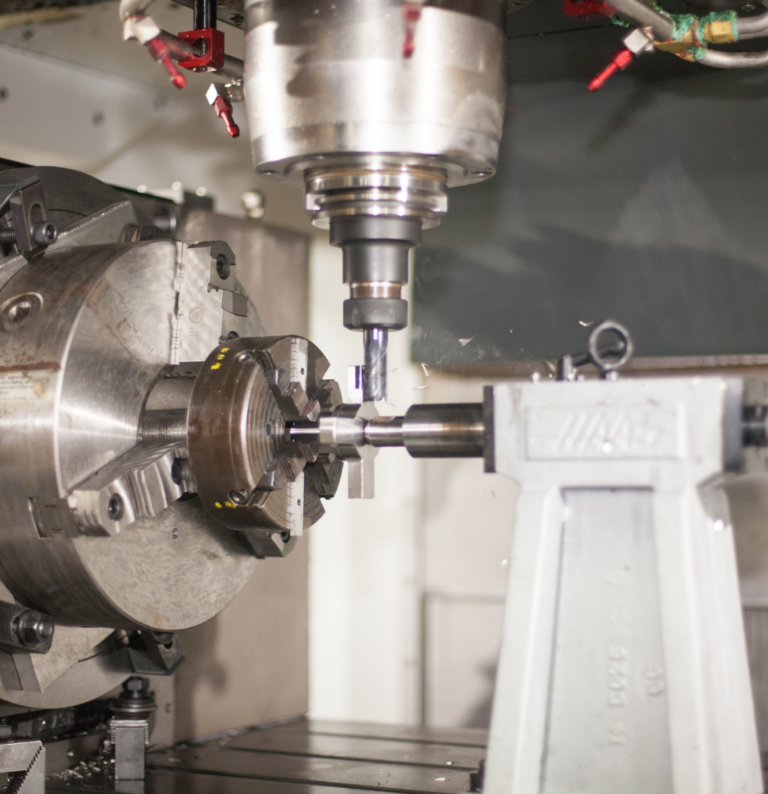

Bonnot provides original parts to you at cost effective prices with quick delivery. So, if your machinery is custom our parts department will work with you to ensure you have the parts you need. We continuously invest in the latest CNC machine technology to ensure the fast turnaround of precise and consistent replacement parts. However, we always recommend that you keep bearings, bushings, seals, and gears on your shelves to help you avoid unnecessary downtime.

Did you know? Our barrels are design to accommodate barrel liners, made of hardened CA40 for maximum durability and cost effective replacement. And our augers have a Stellite 6 weld on the flight periphery that provides excellent cost to wear life ratio. It also means that a customer can return worn augers to us and we can rebuild the flights to as-new OEM condition.

We don’t have to build you something brand new. Sometimes a rebuild can be better!

Here at Bonnot we also specialize in refurbishing and rebuilding our equipment and parts, which means that sometimes a rebuild can be a more cost effective solution. We can return the equipment and parts to original factory condition, and also take this opportunity to improve the design by incorporating newer technology.

This approach can be a more cost effective option for you when you’re looking to increase production. We can work with you to provide a recurring rebuild program that will save you money and reduce downtime.

When a machine needs to be rebuilt, we offer complete tear down services where your machine will be taken apart entirely, all parts inspected and rebuilt where appropriate to OEM specifications. All bushings and seals are replaced at this time also to return a machine to you ‘as new’.

At Bonnot we have full manufacturing capabilities in house, so we can respond to emergencies for all parts in a very quick fashion. Please contact us if we can help you with anything we’ve touched on here…

We are here to help you! Contact us with any questions.

QUOTE REQUEST