Carbon & Char Extruders

We have a long history of processing activated carbon, biochar and other carbon products

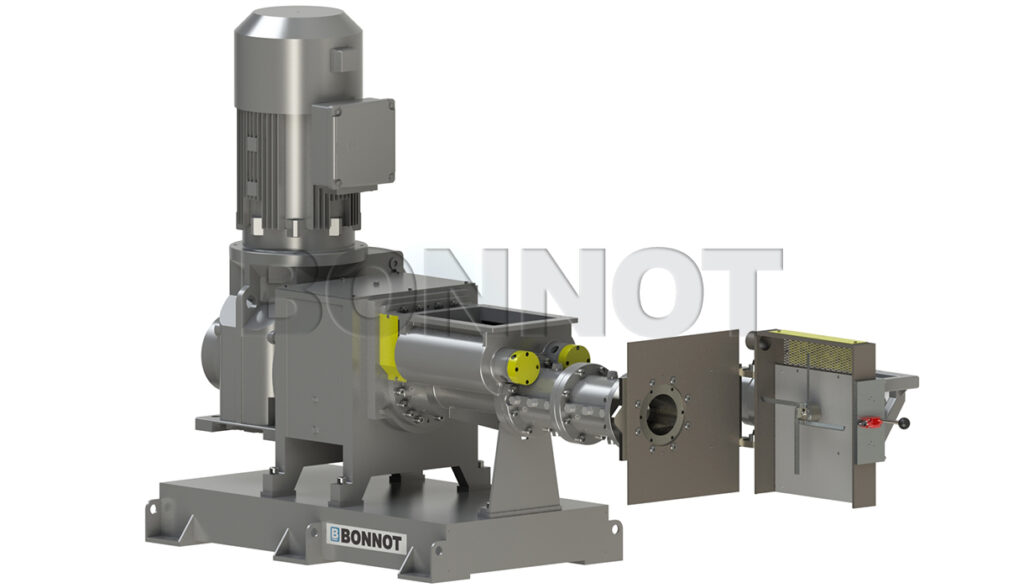

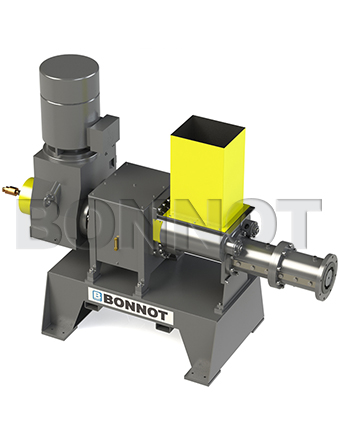

The Bonnot Company builds rugged, robust designs for processing a variety of carbon-based products. Often, the goal is to pelletize or shape carbons with minimal binder that could negatively impact the final product functionality or economic feasibility. Our designs deploy configuration to aid dryer material processing.

Formulations typically include a starch, lignen or polymer binder.

Defining carbon processing formulations can be a challenge. The Bonnot Company is pleased to offer feasibility testing at our facility in Akron, OH, USA and a leasing program for trials at customer facilities.

Extruder Design Features

- Twin Packers for easy material ingestion

- Hard surfacing and replaceable wear resistant barrel liners

- Jacketed barrel for temperature processing control

- Customizable dimensions & configurations

Extruder Standard Specifications

|

Model

|

|||||

|---|---|---|---|---|---|

| Output | 5-15 lbs/hour | 100-175 lbs/hour | 600-1000 lbs/hour | 1500 - 2500+ lbs/hour | 2000 - 3500+ lbs/hour |

| Layout L x H x W | 21" x 22" x 16" | 43" x 54" x 35" | 76" x 79" x 50" | 96" x 82" x 40" | 120" x 77" x 83" |

| Hopper Opening | 3” x 2.4” | 6” x 5” | 11.75” x 9.88” | 18” x 13.5” | 20.5" X 17" |

| Motor HP | 0.5 | 10 | 25 | 75 | 125 |

| Contact Components | Proprietary Stainless Steel | Proprietary Stainless Steel | Proprietary Stainless Steel | Proprietary Stainless Steel | Proprietary Stainless Steel |

|

Model

|

CB 1 Series |

CB 2 Series |

CB 4 Series |

CB 6 Series |

CB 8 Series |

|---|

Relevant Ancillary Equipment

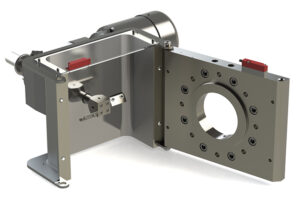

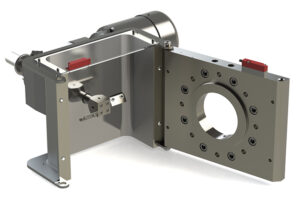

Extruder Cutter

We offer a range of cutters for our extruders.

Extrusion Dies

Bonnot Offers a Variety of Extrusion Dies in Various Sizes

Extruder Controls

The Bonnot Company Offers a Full Range of Control Options For Our Extrusion Systems

Want to Prove it Out?

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.