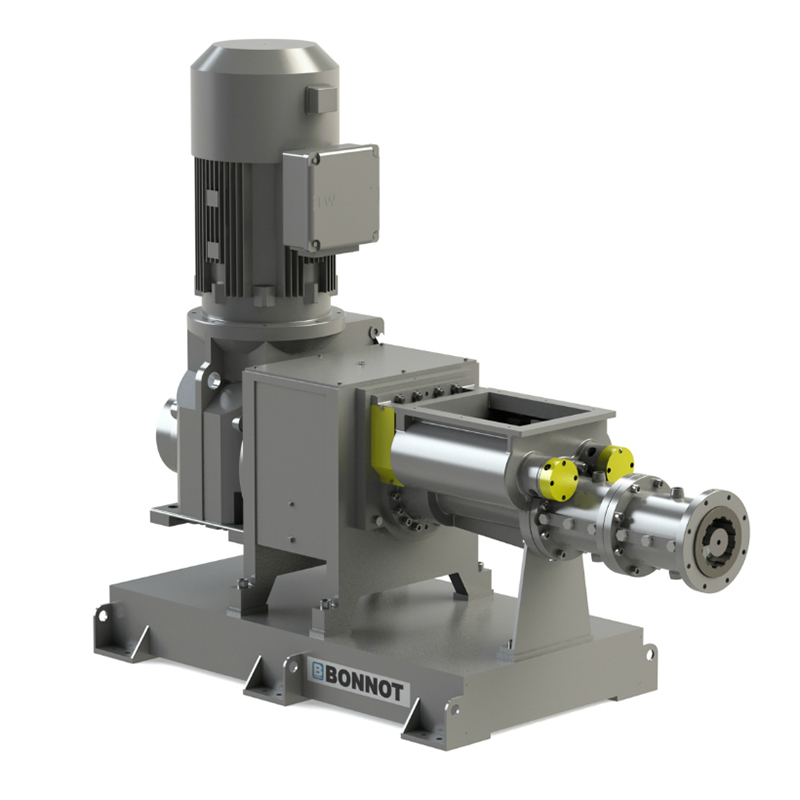

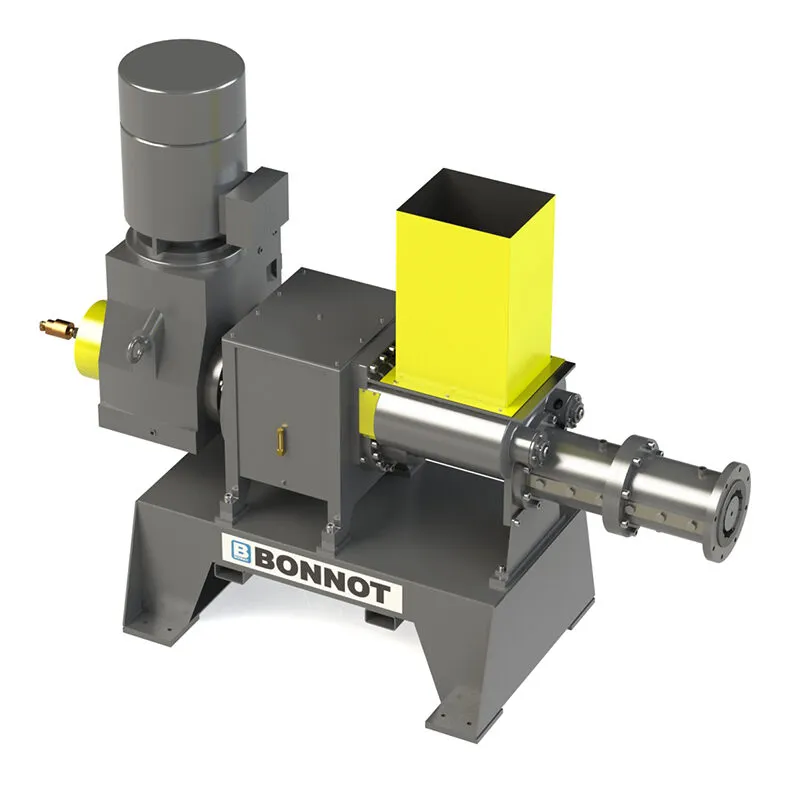

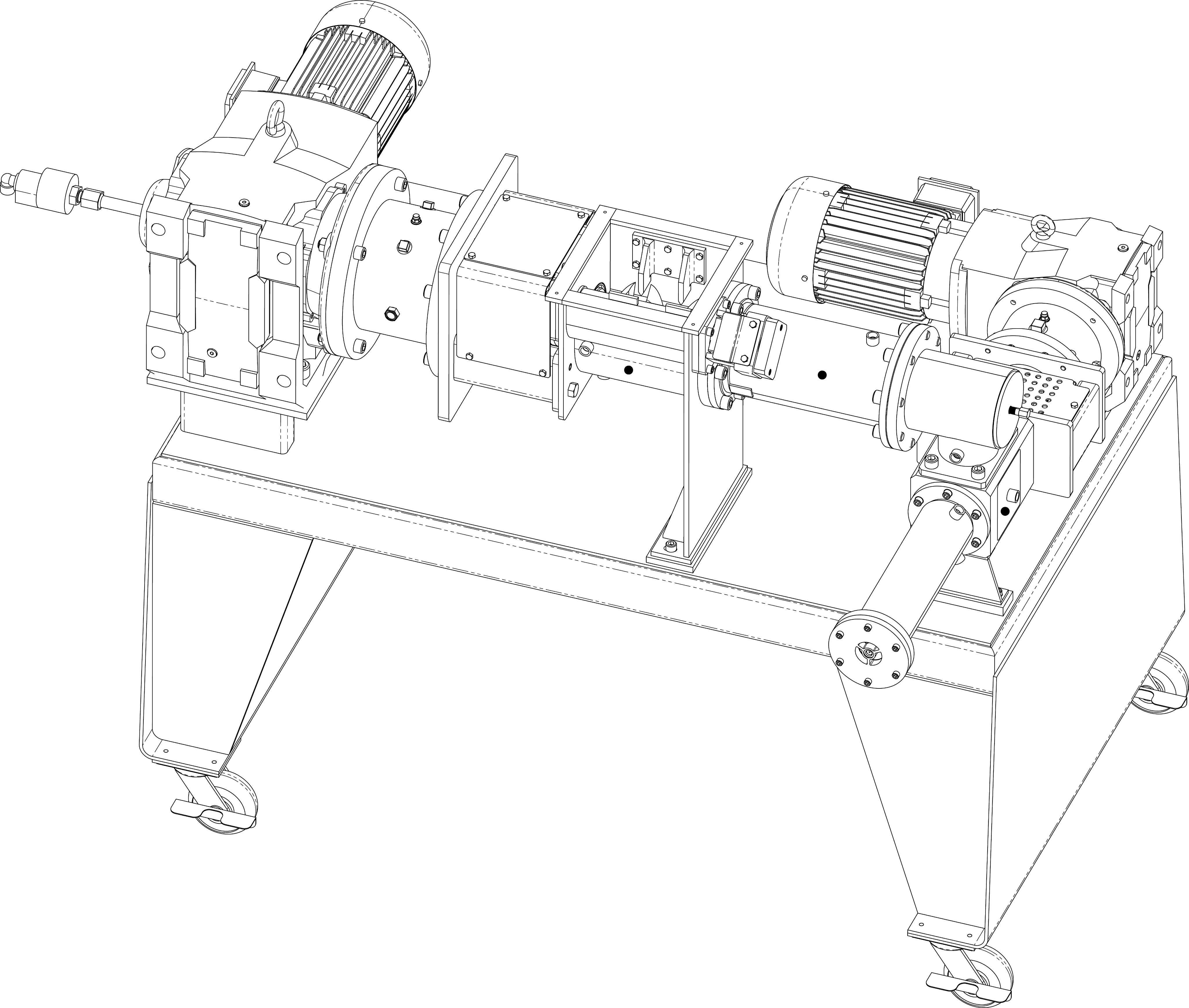

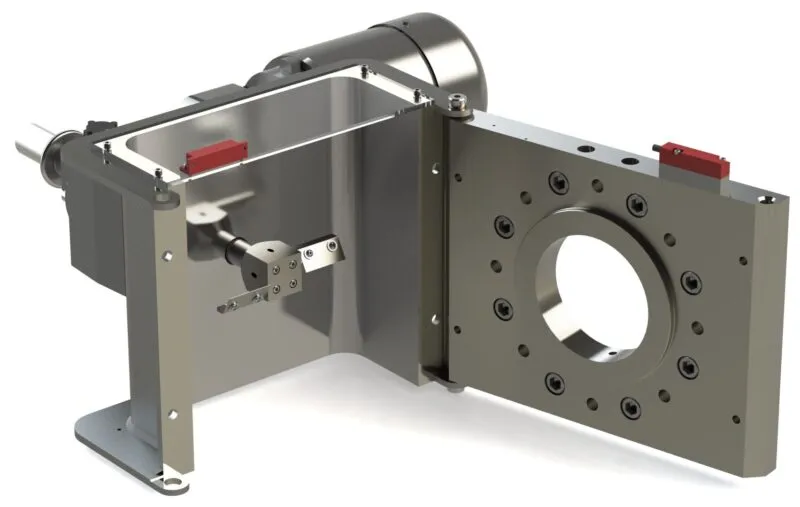

Extruder Design Features

+ Extrude high surface area shapes such as cylinders, hollow tubes, trilobe, quadlobe & more

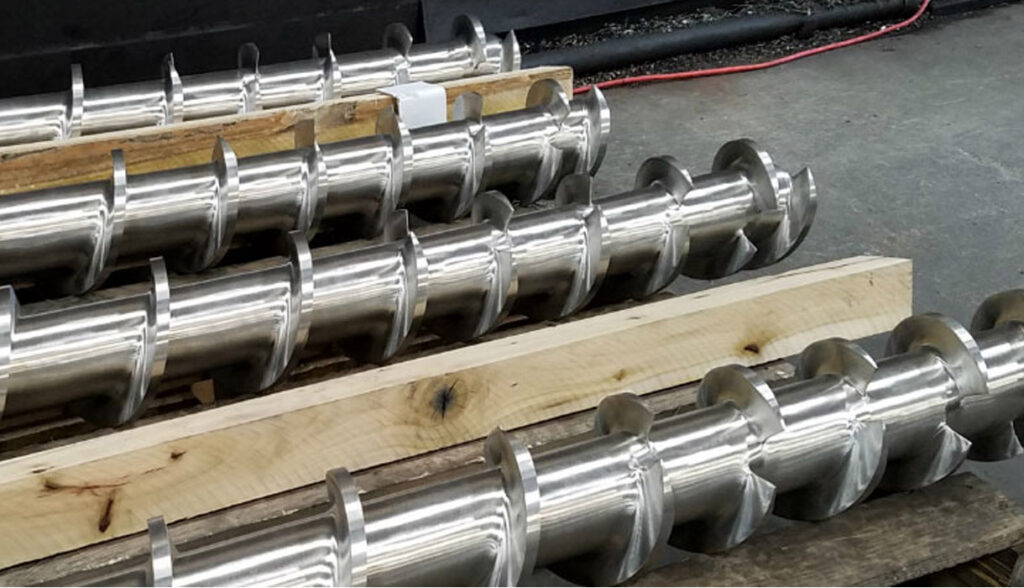

+ Designed for continuous production with proven wear resistant replacable contact components

+ Customized and configured for the specific application

+ Auger rebuild program and barrel liner replacement service

+ Temperature control features

+ 50+ years of proven operation with worldwide install base