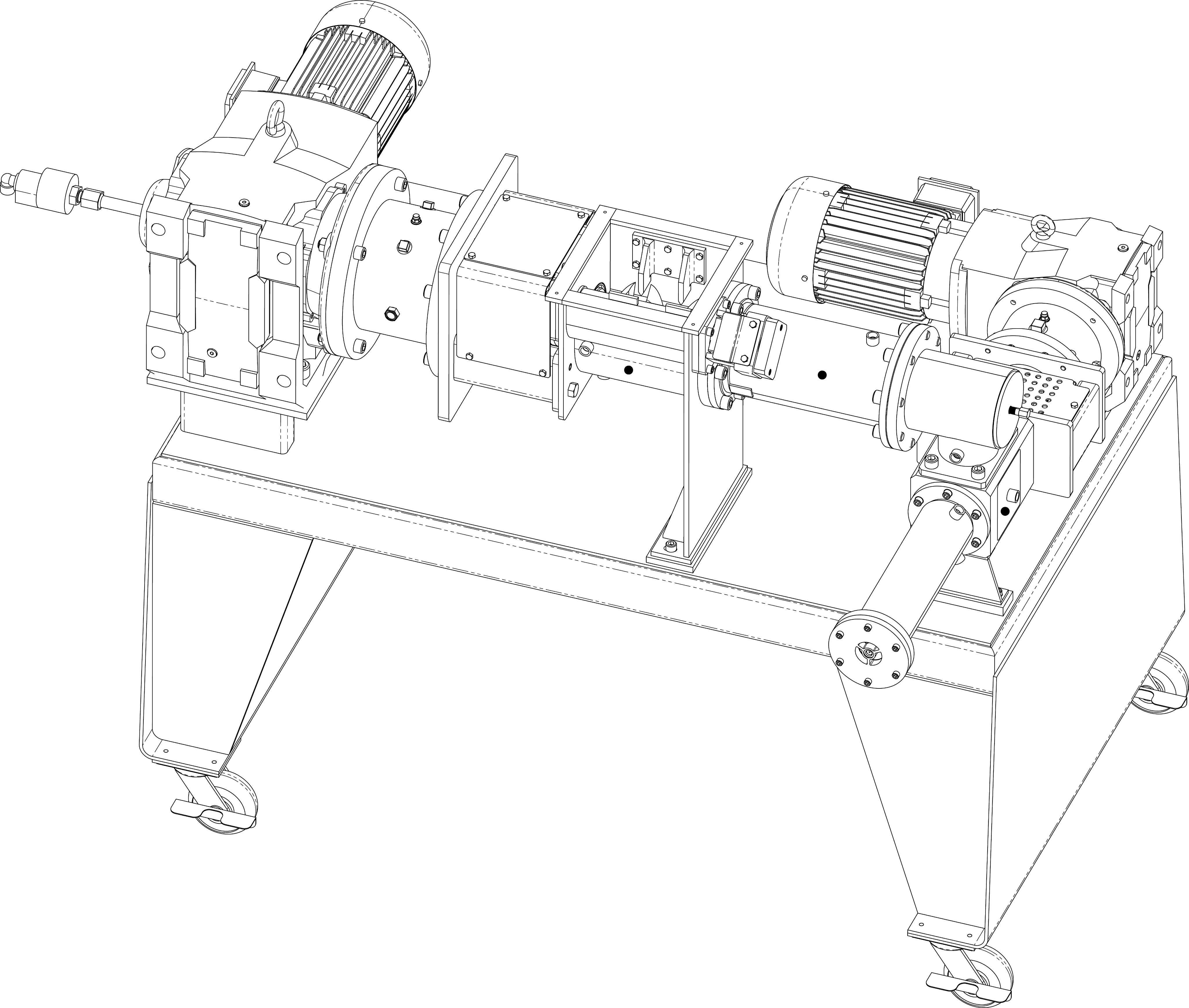

Horizontal Bale Feeders

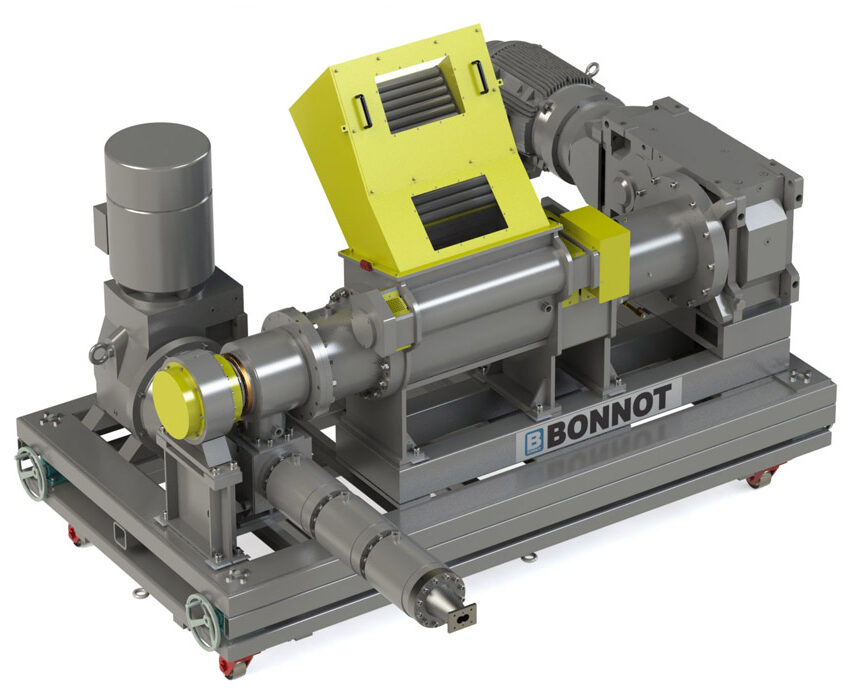

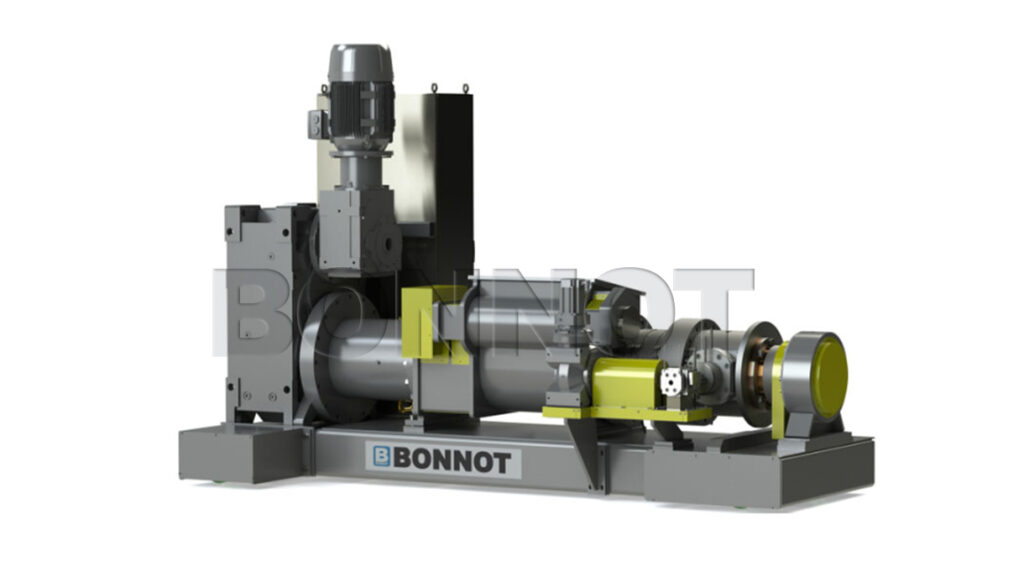

Designed to Process Full Rubber Bales for Pelletizing or Compounding

Bonnot developed the Horizontal Bale Feeder to ingest high viscosity rubbers, including full bales, and process them into pellets or directly feed a compounding extruder.

Extruder Design Features

1Large Diameter Feed Screw, Packer & Rake

2Five Jacketed Zones for Temperature Control

3Pressure Sensitive Screw Design

4Pressure Feedback Loop

5High Torque Gear Motor

6Dual Drive High Torque Gear Motor

Specifications

Extruder Standard Specifications

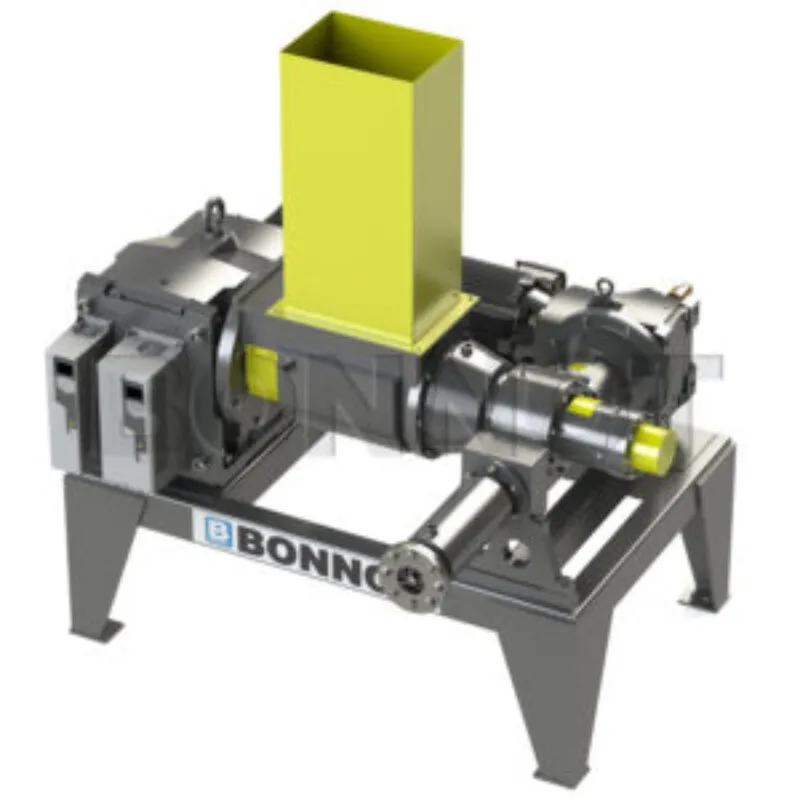

RF 2 Series

- Output

- 50-200 lbs/hour

- Layout L x H x W

- 51” x 64” x 54”

- Hopper Opening

- 9" x 8.5"

- Motor Power

- 3 HP / 3 HP

Ingesting a Full Bale

In this video you can see the Bonnot Horizontal Bale Feeder ingesting a full bale of rubber.

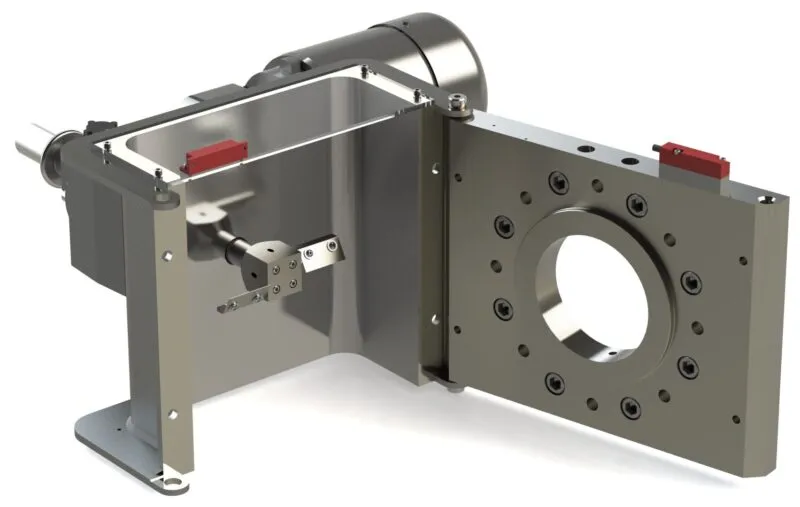

Bale Feeder with Gear Pump

This design enables full bale feeding with highly metered low output using a gear pump.

Trusted by the Best

Want to prove it out?

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.

Get in touch with us