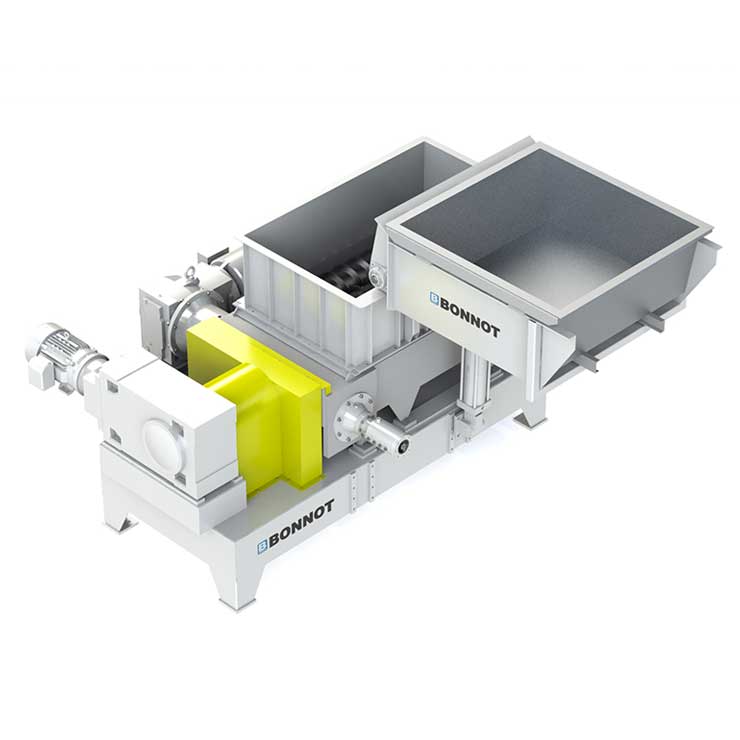

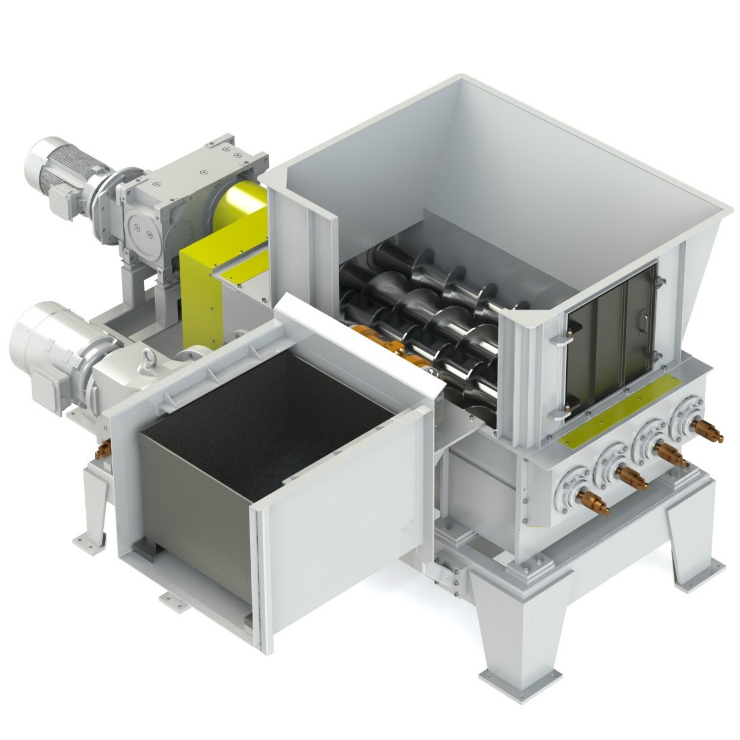

Live Bottom Feeder

Product Information

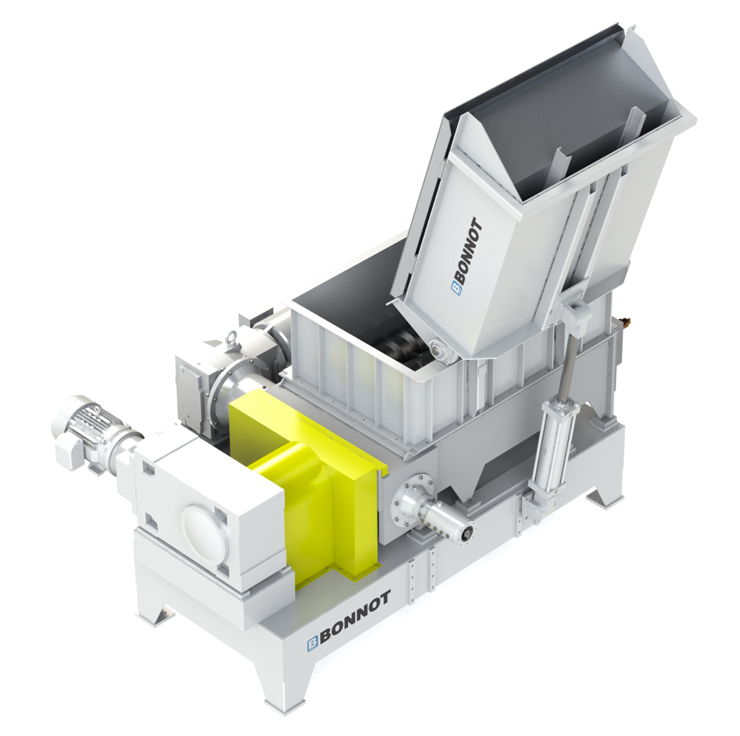

The Bonnot Live Bottom Feeder is designed for uniform, positive feeding of large batches of highly sticky and difficult to handle materials and compounds which do not feed satisfactorily by conventional means. The Live Bottom feeder will help eliminate dumping the mixed batch onto the floor for manual cutting of loafs. This will create a cleaner product and safer work environment for your employees. Integrating the Batch Handling System with the Live Bottom Feeder will allow batches as large as 3500 pounds to be dumped into the Live Bottom. The Live Bottom Feeder can be customized to match mixer capacity.

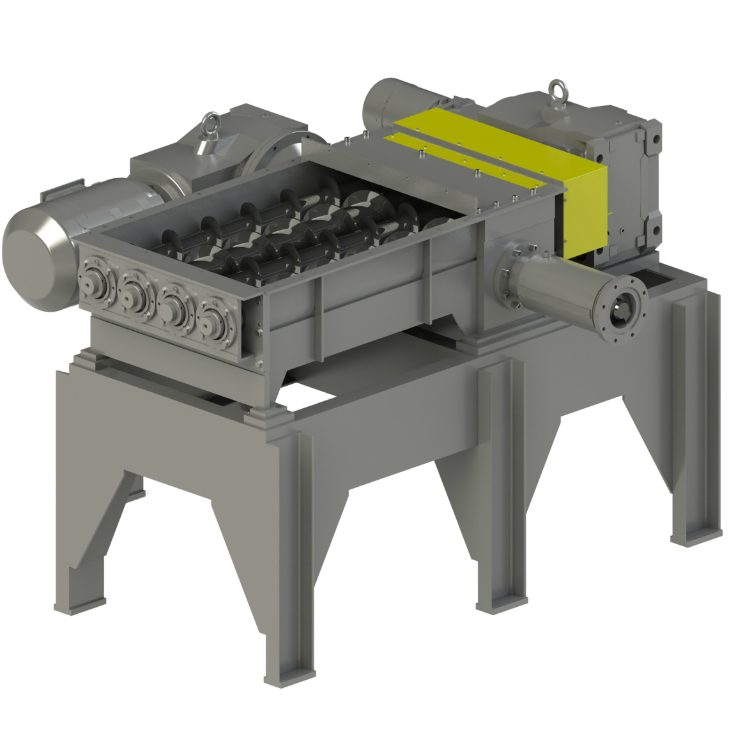

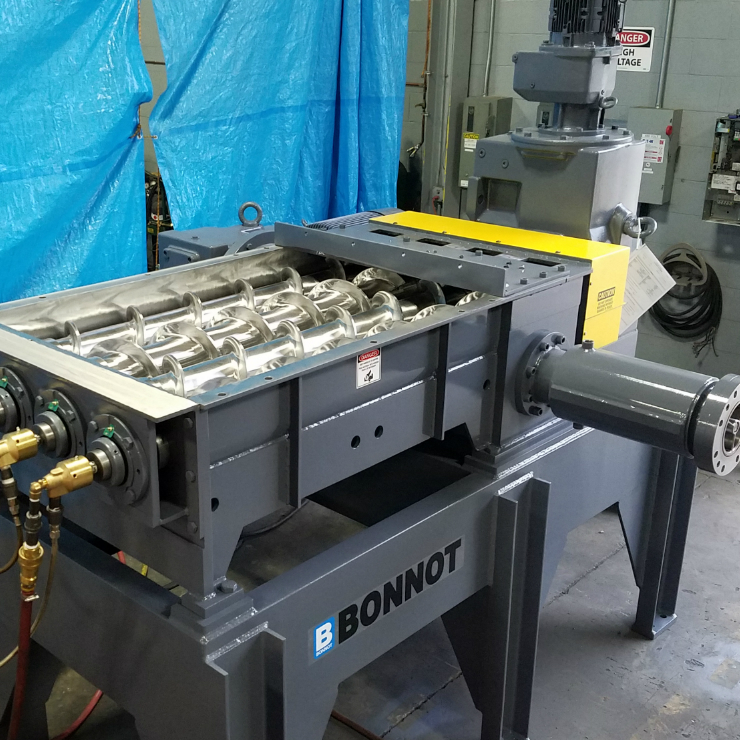

Bonnot Live Bottom Feeder Models and Features

- Available in 4”, 6”, 8” sizes (Bonnot Extruder sizes are identified by auger diameter)

- Capacity: 50 pounds to 3500 pounds per hour

- Large capacity feed hopper for batch loading

- Jacketed barre(s)

- 2-6 feed augers

- Various auger designs including hollow center for temperature control

- Custom metering augers available

- Construction of stainless or carbon steel contact components

- Customizable motor and reduce configurations for specific output and torque

Contact our Bonnot Experts and we will be in touch within 1-2 business days to discuss your needs.

Quote Request

Live Bottom Feeder Primarily Served Applications:

- Butyl Rubber

- Silicone Rubber

- Mastics Wax Compounds

- Food/Pet Food

- Other Sticky Materials