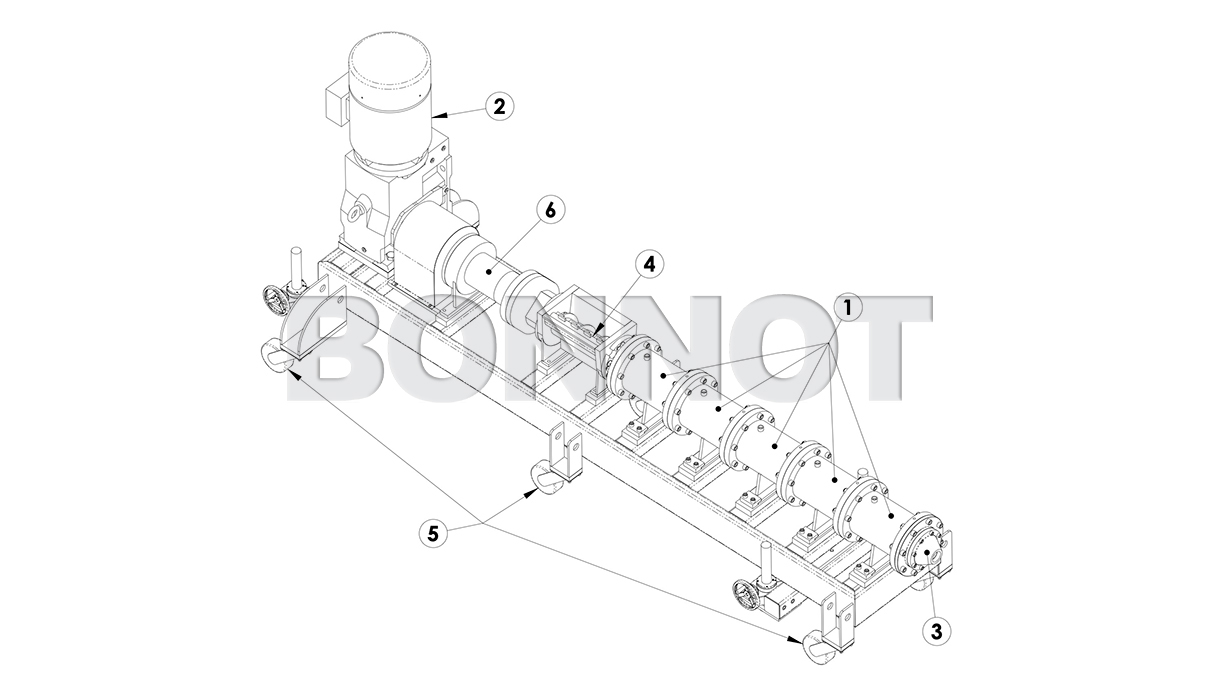

Cold Forming Extruders

We Have a Long History of Manufacturing Continuous Cooling and Forming Extruders

The Bonnot Company offers a line of Cold Formers designed to continuously cool and extrude cooked doughs into pellets or shapes. A wide variety of breakfast cereals, snack foods, soft moist pet foods are produced on our Cold Formers. Our designs have a hollow screw, shallow flights, and jacketed barrel sections to optimize continuous cooling. They can be configured with a counter rotating packer in the hopper above the screw to enhance feeding of difficult materials. The systems come in a variety of sizes to meet your production requirements. The designs conform to the latest food safety and sanitary requirements.

Extruder Design Features

- Designed to maximize thermal transfer

- Multiple cooling zones for process control

- Hollow, shallow flighted screw to supplement barrel jacket cooling

- Customizable dimensions

- Configured for your specific application

Extruder Standard Specifications

|

Model

|

||||

|---|---|---|---|---|

| Output | 500lbs - 2,000lbs | 1,500lbs - 5,000lbs | 1,500lbs - 6,000lbs | 2,000lbs - 7,500lbs |

| Layout L x W x H | 96" x 36" x 36" | 108" x 42" x 36" | 144" x 54" x 36" | 168" x 84" x 36" |

| Approximate Weight | 3200lbs | 4,500lbs | 7,500lbs | 8,900lbs |

| Motor | 25 HP | 40 HP | 40 HP | 50 HP |

| L/D | 10/1 | 10/1 | 10/1 | 10/1 |

| Contact Components | Food grade stainless steel | Food grade stainless steel | Food grade stainless steel | Food grade stainless steel |

|

Model

|

CF 6 Series |

CF 8 Series |

CF 10 Series |

CF 12 Series |

|---|

Major Customers

Relevant Ancillary Equipment

Extruder Controls

The Bonnot Company Offers a Full Range of Control Options For Our Extrusion Systems

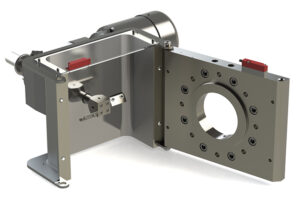

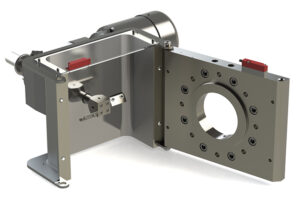

Extruder Cutter

We offer a range of cutters for our extruders.

Extrusion Dies

Bonnot Offers a Variety of Extrusion Dies in Various Sizes

Want to Prove it Out?

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.