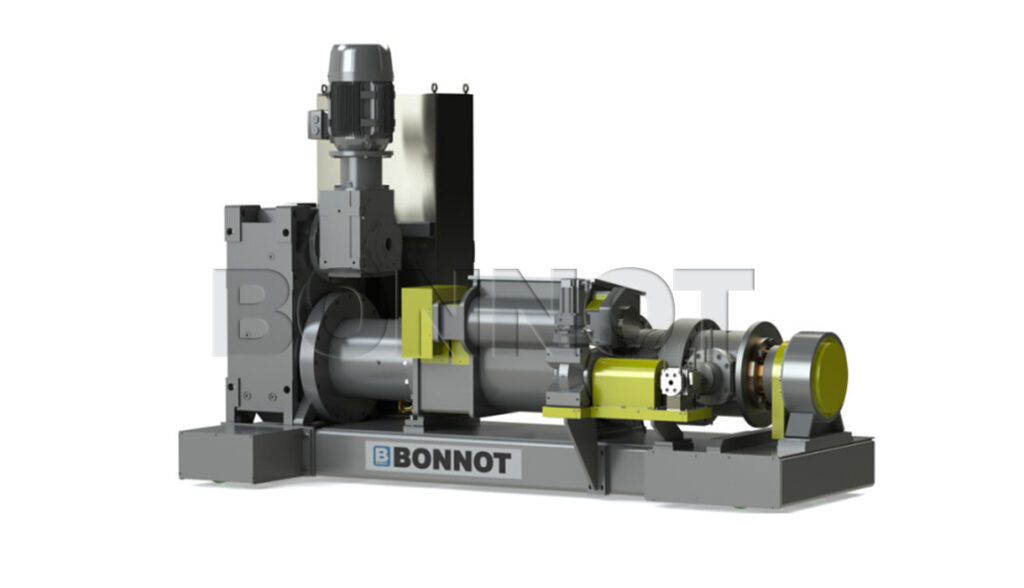

Custom Extruders

For 130 Years, The Bonnot Company has Specialized in Custom Development of Extruders

The Bonnot Company specializes in custom extruder design development to achieve customer objectives when standard commercial offerings fall short. Drawing on our 100+ years of experience with manufacturing extruders, we have developed a multitude of specialty equipment. Our existing designs act as a starting point, then conducting trials in our Test Facility we are able to refine and optimize the extruder configuration to meet customer requirements. Bonnot custom extruders can be designed with a wide variety of size, screw geometries, length-to-diameter ratios, horsepower, RPM ranges and controls to optimize your application.

Customization Options

- Custom feed sections to accommodate your batch size

- Packer, Screw Geometry & Die Shape

- Custom contact component material selection to resist wear and corrosion

- Temperate Control Manifold

- Designs suitable for higher torque loads and to match the exact throughput you need

- Custom bases to match centerline height with takeoff equipment or to add casters for mobility to fit your plant layout

- Custom designs for cleanability to aid with faster material changeovers

- Custom dies to match the desired shape and size of your extrudate

Major Customers

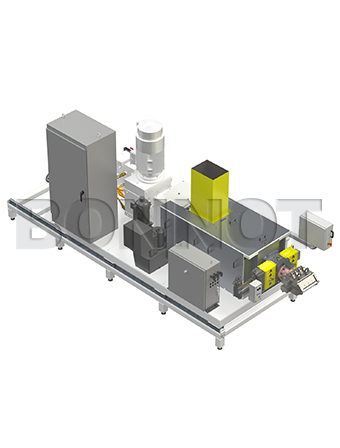

Relevant Ancillary Equipment

Extruder Controls

The Bonnot Company Offers a Full Range of Control Options For Our Extrusion Systems

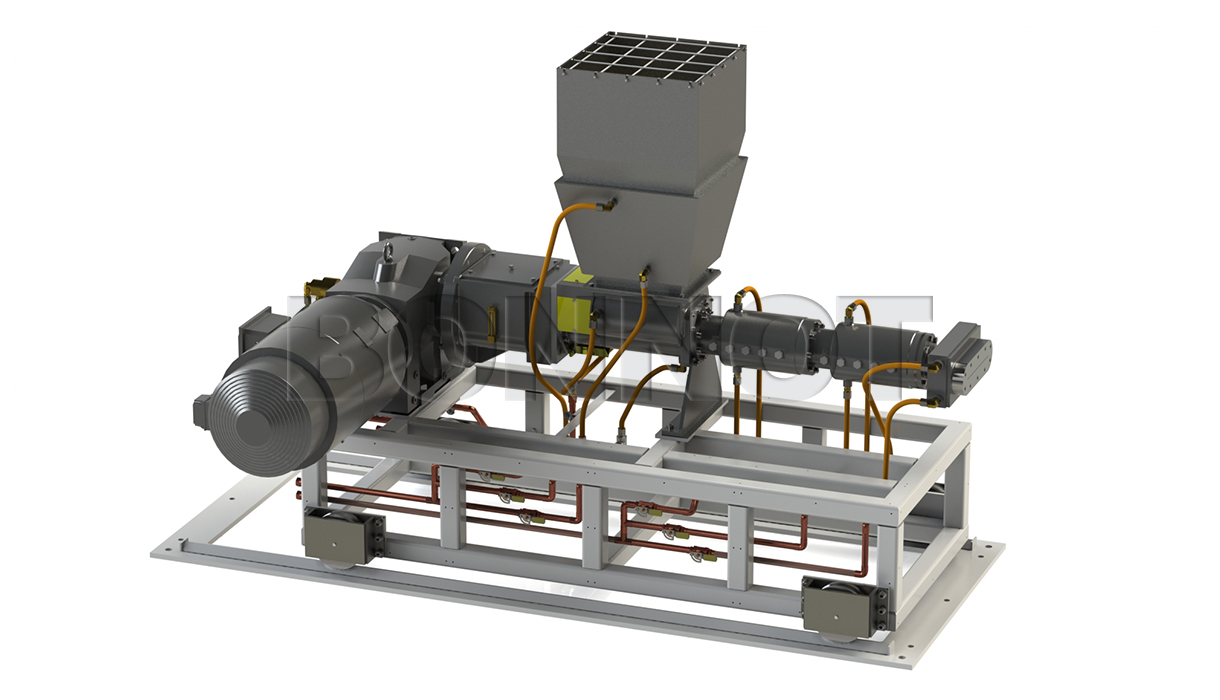

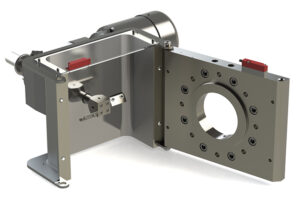

Extruder Cutter

We offer a range of cutters for our extruders.

Extrusion Dies

Bonnot Offers a Variety of Extrusion Dies in Various Sizes

Want to Prove it Out?

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.