February 12, 2026

An Introduction to Single Screw Extruders

Explore the basics of single screw extruders—how they work, core components, advantages, and common manufacturing applications.

7th August 2018

Words, such as pellet, briquette, nodule, ball, sphere and compacting, all relate to some type of agglomeration and are familiar to all of us.

Agglomeration has become an essential operation for reasons, such as processed material in some cases can shipped without special packaging, reduction of fines and dust, easier and more efficient handling, less volume for a given weight, and there are even some instances where the finished product is psychologically more attractive. Also, when the finished product consists of two or more ingredients, agglomeration will provide uniformity and prevent separation.

For a good number of years most of the information and formulas that could accurately be applied regarding the behavior of materials in a screw extruder were derived from truly plastic materials and were also used for scale-up.

Over the past years, due to the needs and demands of various industries, we have become involved in material extrusion for a wide range of minerals, chemicals and synthetic compositions to which the rules and formulas do not truly apply. Unfortunately, many of these materials or compositions have little or no plasticity and by themselves, have no flow characteristics whatsoever.

Materials that have no inherent flow characteristics cannot be extruded due to the fact that the screw or auger will not push the “no flow” material through the forming die, but instead will compact it solid against the backside of the die, resulting in either jamming and stalling the extruder, fracturing the die plate, or breaking the augers. Any of these could severely damage the extruder proper.

When we encounter such materials, we conduct tests relying on experience, customer assistance or recommendations, R&D data, and actual customer applications, to attempt to find something that can be mixed with the material to produce the plasticity necessary for extrusion.

In some rare instances, simply adding water and mixing is sufficient, but in most cases it is not that easy and generally requires special additives or extrusion aids. Fortunately, many are now commercially available. In most cases, these additives also act as binders.

In a few cases, even with a suitable additive, it has been found that due to the nature of the base material, intensive auxiliary mixing is required to properly condition the material. There are also some that have been found to require a tempering period as long as 90 minutes after mixing, prior to extruding.

In any situation where some type of additive proves to be successful from the extrusion standpoint, there are a variety of tests conducted to evaluate extruded samples, and if the results are satisfactory, then the overall extrusion process and requirements must be studied from a production standpoint to determine the financial feasibility.

Some typical examples of materials and products utilizing screw-type extruders successfully today would be as follows:

A wide variety of catalyst materials, including aluminas, kaolin, molecular sieves, etc., in cylindrical shapes as small as 1/16” diameter, and in some cases a rotary cutter for die face cutting is incorporated. Monolith and ring-type products can also be formed using special dies. Some pellets are also tumbled after extrusion to product spheres.

For face soap and specialty bars, the extruder is used for producing a de-aired round slug that is cut to a given weight for subsequent pressing and stamping into individual shapes.

Blackboard chalks and pastels are extruded in a large variety of shapes and sizes.

For chewing gum and bubble gum, the extruder forms a rope or rod pre-formed which is passed through a special machine for final sizing, cutting, and wrapping.

A wide variety of breakfast cereals and snack items, expanded and non-expanded, are cooked and gelatinized using a high temperature, high pressure extruder. Most of these items are “half products” and require further down-stream processing, such as drying, coating, deep-fat frying, etc.

Synthetic wax based fire logs are made up of practically any combustible material, using slack wax or petroleum as the binder. Coal with binders can also be extruded in a log, briquette, or pellet form.

Fertilizers for house plants, tree spikes, etc., is extruded in a variety of sizes and shapes.

Some pharmaceuticals are extruded into very small particles of the type found in cold capsules.

Time does not permit listing and describing the many applications. However, some others are: abrasive tumbling media, butyl sealants, mastics, caulking, pet food, yeast, rodent and roach bait, charcoal briquettes, floor tile, bricks, clay pipe, electrical porcelain insulators, toilet bowl deodorants, modeling clay, special surgical pads, some candy items, cheese, polyester and alkyd molding compounds, a variety of filter cake materials, friction products, explosives, carbon, pretzel sticks, diatomaceous earth, zirconium, EPDM rubber, natural bale rubber, and the list goes on and on. Hopefully, however, this provides some insight into the wide range of products for which screw extrusion can be considered as a possible means of processing.

There are, of course, some applications concerning particular products that cannot be discussed in detail due to confidentiality agreements with our customers.

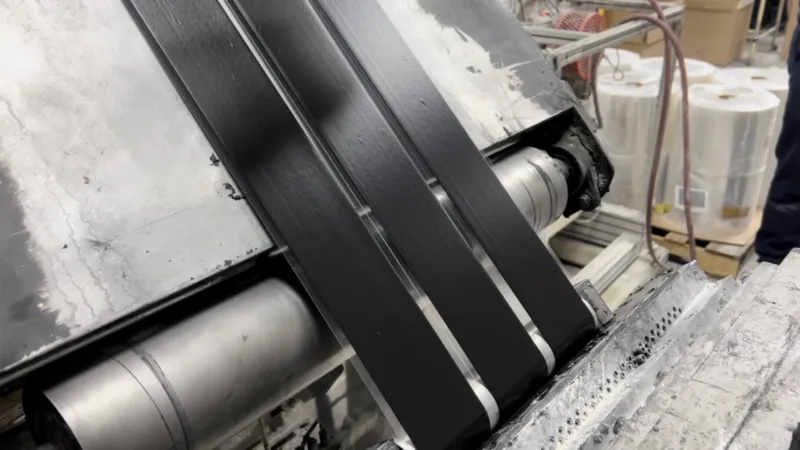

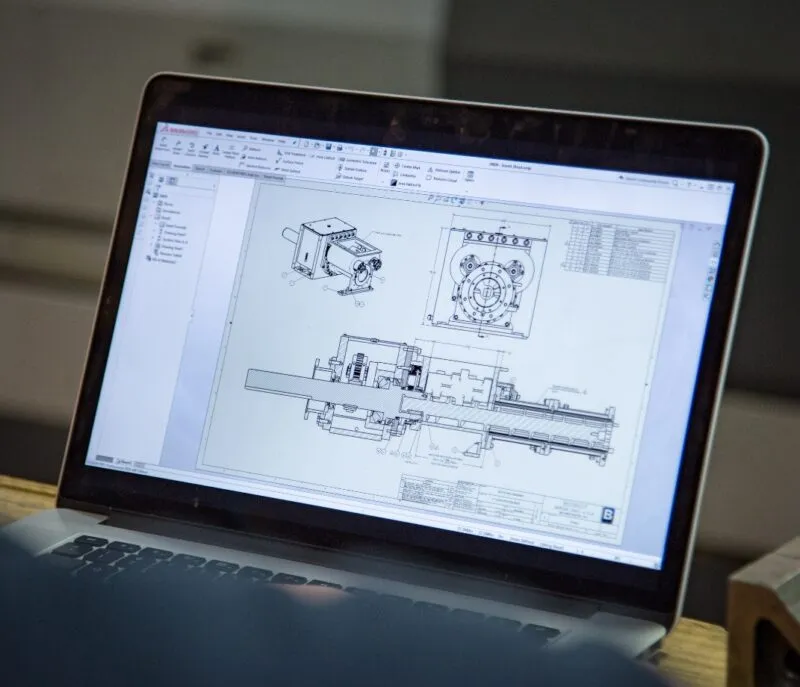

Extruders are manufactured in a very large range of types and sizes, such as an in-line machine wither either continuous flights or interrupted flights and pinned barrels, two-stage and in-line vacuum units, twin screw (counter-rotating and intermeshing), horizontal feed and extrusion screws in one combined unit, and practically any type of custom units in sizes from 1” screw diameter for lab and R&D work, up to as large as 18” screw diameter for high tonnage production. A variety of screw configurations are available and the machines are designed for easy replacement of normal wearing parts, like screw, augers, barrels, and barrel liners. Materials of construction vary depending on the requirements of particular applications and material conditions.

Naturally, the initial costs of the equipment cover a wide range depending on a large number of variables, but to give you an idea, the smallest extruder we manufacture sells for approximately $10,000.00 and is essentially a toy compared to a large, high production extruder unit that may cost $750,000.00 or more.

As a general rule, when a screw extruder is put into a system, it will pay for itself in labor savings, etc., in a reasonable period of time. This will vary, depending on the particular product.

Some advantages of screw extruders are the fact that it provides a continuous operation as long as properly prepared material is fed into the machine. This falls in line with automation which is highly desired in this day and age as a means of reducing manpower and labor costs. Also, practically any desired shape and size can be produced simply by changing the forming die.

Maintenance costs, including labor and replacement parts, are kept to a minimum due to the fact that these matters are a prime consideration in the original design of a machine. We think we have done a pretty good job in this respect as evidence by the fact that our parts department still supplies parts for machines built back as far as 1910 and are still running.

February 12, 2026

Explore the basics of single screw extruders—how they work, core components, advantages, and common manufacturing applications.

September 27, 2024

The Bonnot Company has manufactured a line of extruders for processing butyl/mastic rubbers (butyl) since the 1950's. The company recognized the need to offer processing extruders for this rapidly developing market. In keeping with a core principle of continuous improvement, these designs have evolved over time to remain the pre-eminent industry choice for butyl processing equipment/extruders.

September 19, 2024

The Bonnot Company has a variety of custom extruders designed for bulk feeding of rubbers, both natural and synthetic, silicones, butyls and mastics. Regardless of the batch size or material viscosity, there is a solution available. If one of the company's standard designs does not meet your needs, a custom solution is developed. Customized solutions specifically tailored to a customer's needs are a core competency of ours and competitive advantage.