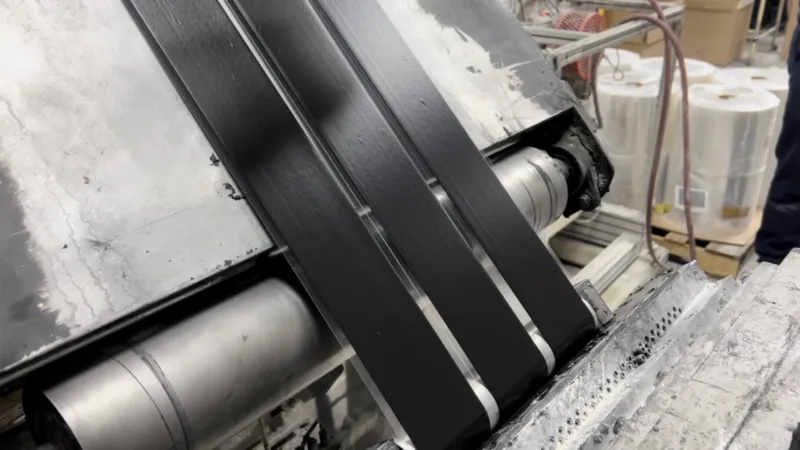

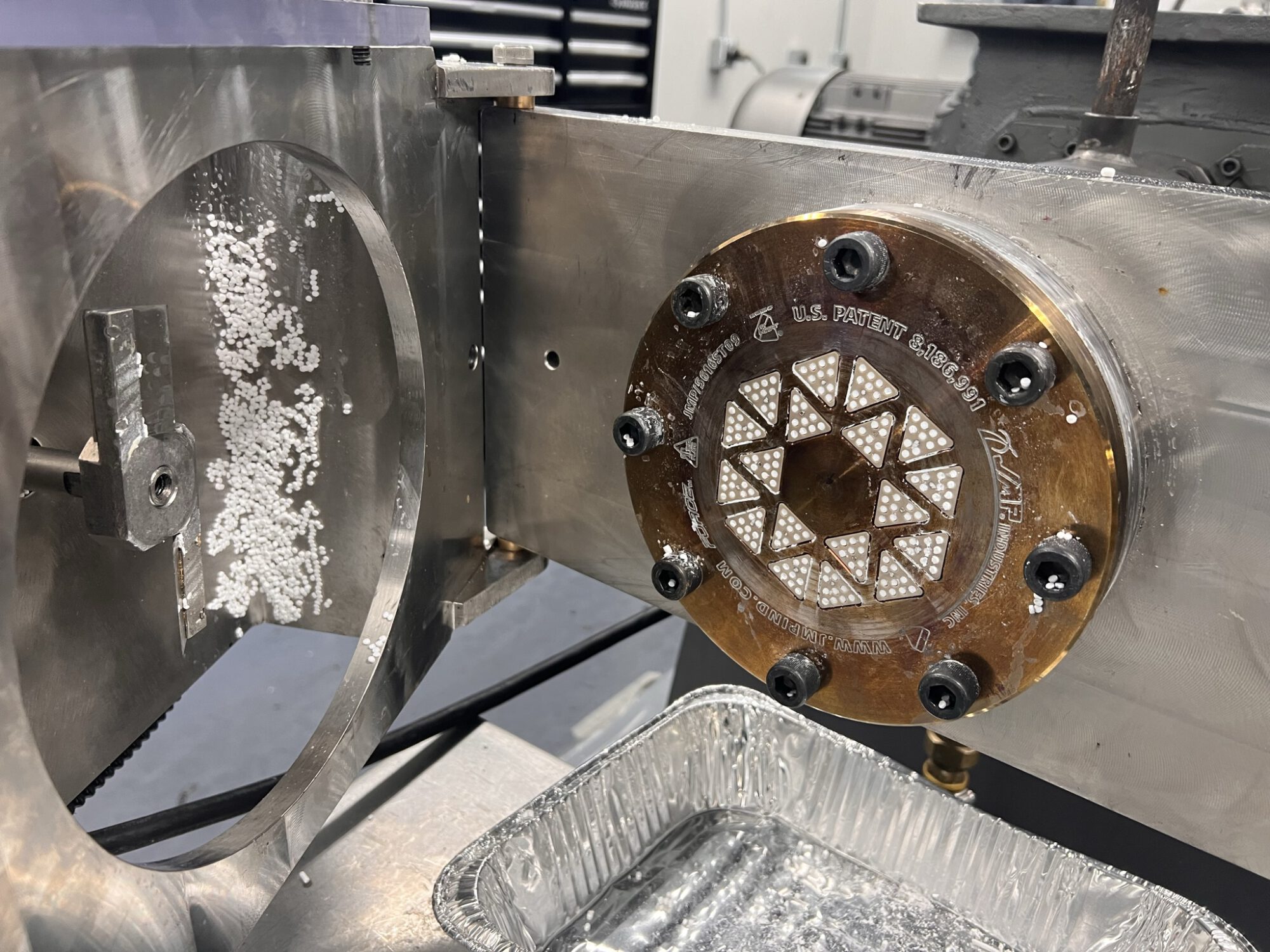

The scope of our testing includes die design. Extrusion dies are a critical component in the formation of the desired product profile. The design difficulty centers on achieving the desired shape within set limits of dimensional uniformity at the highest production rate possible.

Die design criteria considers:

- Open area % – lower = higher pressure

- Thickness – the thicker the die, the greater “land” area, the more drag created, the greater the pressure required to push product, the denser the pellet

- Material of construction (MOC) – varies coefficient of drag (i.e., Delrin vs. steel)

- Addition of a spacer – equalizes the flow across the die by eliminating the leading-edge pressure from the screw flight, creating more uniform length if cutting. Note, not all materials will flow without mechanical aid.

- Addition of heat – often improves flow and/or surface finish of extrudate. Often just a pre-heat at the die face is sufficient.

- Etc.

Another processing variable that we consider is the effect of temperature management. Our Test Facility is fully equipped with temperature control units (TCU) to optimize the extrusion process. Some of the factors they are used for are:

- May be a criterion of the process to heat the product.

- Mechanical energy is generated through shear as material passes through the screw and barrel.

- TCUs are often used to cool or dissipate this heat.

- Basic principle – “stiffer” material pushing softer material.

- If material softens with heat applied, have the first barrel(s) running cooler than the exit barrel(s)/die.

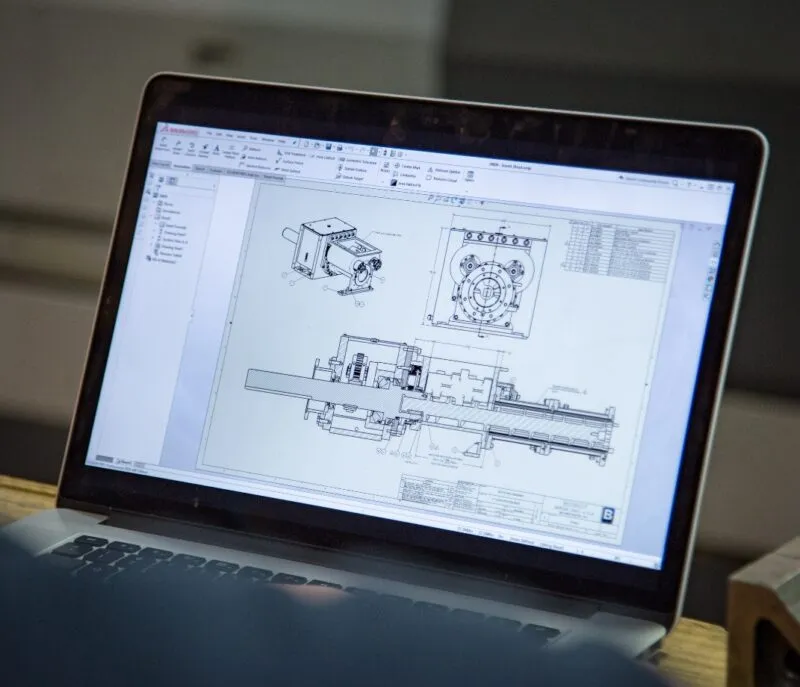

Testing is of course useless if it is not recorded accurately. At Bonnot we pride ourselves in meticulous Data Collection at every stage. Not just what worked, but also what didn’t. So that once a stable output state is reached and you are completely satisfied, we collect and record essential data including operating Amps, HP, RPM, throughput (lb/min.), temperature, pressure, etc.

The test data is then summarized and recorded in a report, including videos, and shared with you.

In short, we record everything. We test everything. And we ensure that you are delighted.