December 5, 2025

An Introduction to Single Screw Extruders

Explore the basics of single screw extruders—how they work, core components, advantages, and common manufacturing applications.

29th March 2019

At the Bonnot Company, we’ve been bringing the best rubber extrusion solutions to our clients for over 25 years. As such, we know all the ins and outs of the rubber extrusion process and when an extruder would be the best fit for a company’s needs. There are several instances we’ve come across when a rubber extruder would help optimize your company’s production process and create an overall safer work environment.

The biggest challenge that manufacturers face when dealing with rubber bales is size reduction. Generally, talc or other special chemicals are used to help break down the rubber and prepare it for the rest of the rubber forming process. The powdery talc has a tendency to get all over the facility, though, and chemicals can be dangerous to handle.

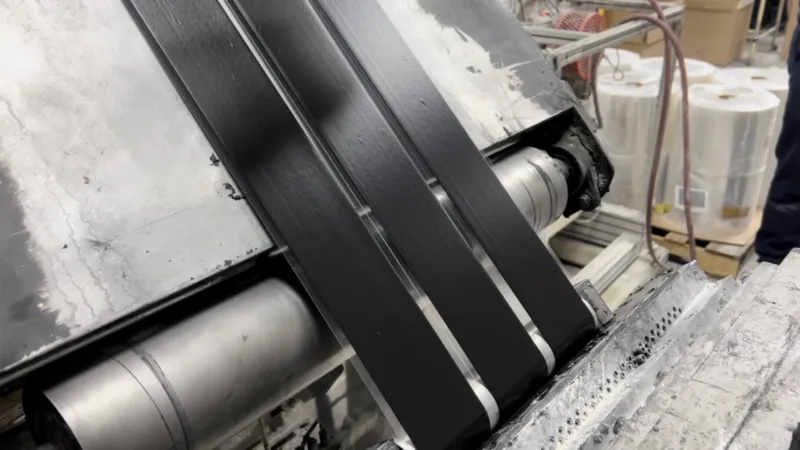

A rubber extruder from Bonnot takes care of this issue. Full and partial rubber bales can be fed into our dual-screw machinery, which breaks the rubber down without the need for talc or chemicals. It’s a more streamlined process that’s ultimately safer for the employees manning the machine.

On the subject of safety, a Bonnot extruder can help with that as well. Not only are talc and chemicals removed from the rubber extrusion equation, but employees don’t even need to manually load the rubber bales into the extruder: they can be fed into the machine via conveyor, elevator or robotic arm. Our machines even produce much less noise compared to the granulators you might currently have in your facility, which can quite literally reduce headaches.

Certain industries within the realm of rubber products manufacturing have stringent regulations on quality. One such example is the pharmaceutical industry, which holds rubber-based products like hydrocolloid, hydrogel dressings and transdermal patches to a high standard for patient safety.

The Bonnot Company is ISO certified and every part of our machines have 100% inspection — we even retain material certification records should you ever need them for a facility audit. These rubber bale feeders are capable of metering your materials to less than 1% variation so you can meet your industry’s standards.

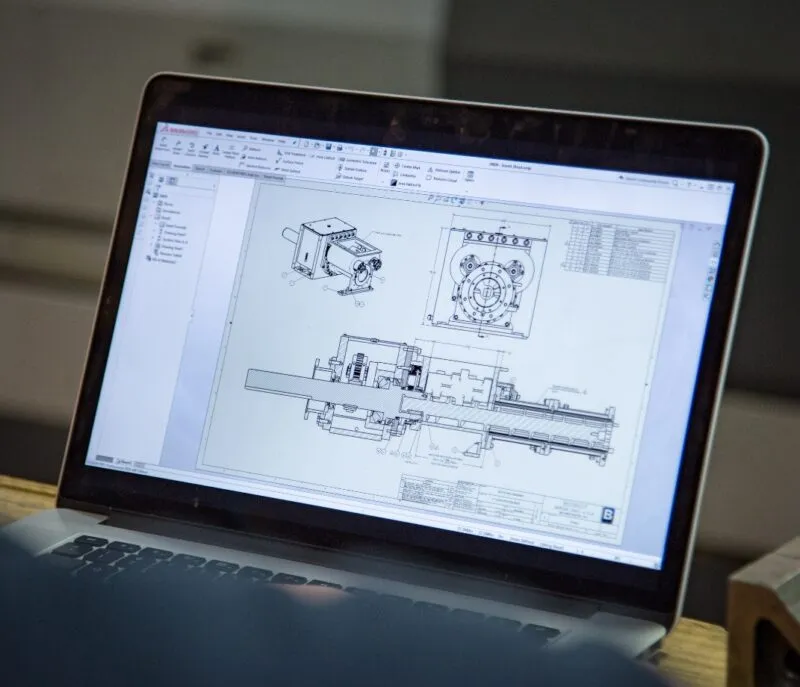

Additionally, our rubber extrusion equipment has five independent temperature zones that allow for precise temperature control. Depending on your needs, the zones can be run in series or parallel to one another. These zones create consistent flow at an optimal temperature so you can create a great finished product every time.

The rubber forming process can get expensive because of the talc and special chemicals typically needed to break down the sticky bales. With a rubber extruder, you immediately experience savings by no longer having to rely on those harsh additives.

Bonnot rubber extruders are also constructed of heavy duty materials that can accommodate the high torque requirements for processing tough rubber bales. The longevity of our thrust bearings is the best in the industry, and our abrasion and corrosion resistant replaceable liners are easy to swap out when the time eventually comes. Our proprietary designs and materials have been field tested for decades, so you don’t have to worry about losing money on downtime for maintenance and replacements.

The Bonnot Company is eager to help your company find the perfect extrusion solution for your company, whether it’s a rubber extruder, bale feeder or other machinery. We have onsite R&D facilities to test out custom solutions for your company’s unique needs, so you only need to reach out to see our equipment in action. View the rest of our extruders and industry applications today.

December 5, 2025

Explore the basics of single screw extruders—how they work, core components, advantages, and common manufacturing applications.

September 27, 2024

The Bonnot Company has manufactured a line of extruders for processing butyl/mastic rubbers (butyl) since the 1950's. The company recognized the need to offer processing extruders for this rapidly developing market. In keeping with a core principle of continuous improvement, these designs have evolved over time to remain the pre-eminent industry choice for butyl processing equipment/extruders.

September 19, 2024

The Bonnot Company has a variety of custom extruders designed for bulk feeding of rubbers, both natural and synthetic, silicones, butyls and mastics. Regardless of the batch size or material viscosity, there is a solution available. If one of the company's standard designs does not meet your needs, a custom solution is developed. Customized solutions specifically tailored to a customer's needs are a core competency of ours and competitive advantage.