One of the most versatile materials used in modern manufacturing is, without a doubt, plastic. In order to form plastic into the many shapes, sizes and structures required to create a diverse catalog of products, plastic extruders are necessary.

How Does Plastic Extrusion Work?

Much like any other form of extrusion, plastic extrusion begins by passing raw plastic materials and any additives (like chemical supplements for UV resistance) through a heated chamber or heated zones. Sometimes, heat is not needed, and the raw materials are melted through friction and pressure at the beginning of the manufacturing process.

After reaching the breaker plate, which removes impurities, creates back pressure and straightens the plastic, the molten material is pushed through a die to be shaped into the profile of your product or part. These dies can be any shape or pattern desired, depending on the kind of product you want to create. The Bonnot Company has an entire R&D facility dedicated to developing the right die and extrusion solutions for your unique needs.

Cold feed extrusion and plastic injection molding are also methods that can be used to create plastic products. Cold extrusion can be performed using a plastic extruder machine, while injection molding forms products by clamping together two hollow cavities and allowing the plastic to cool and harden.

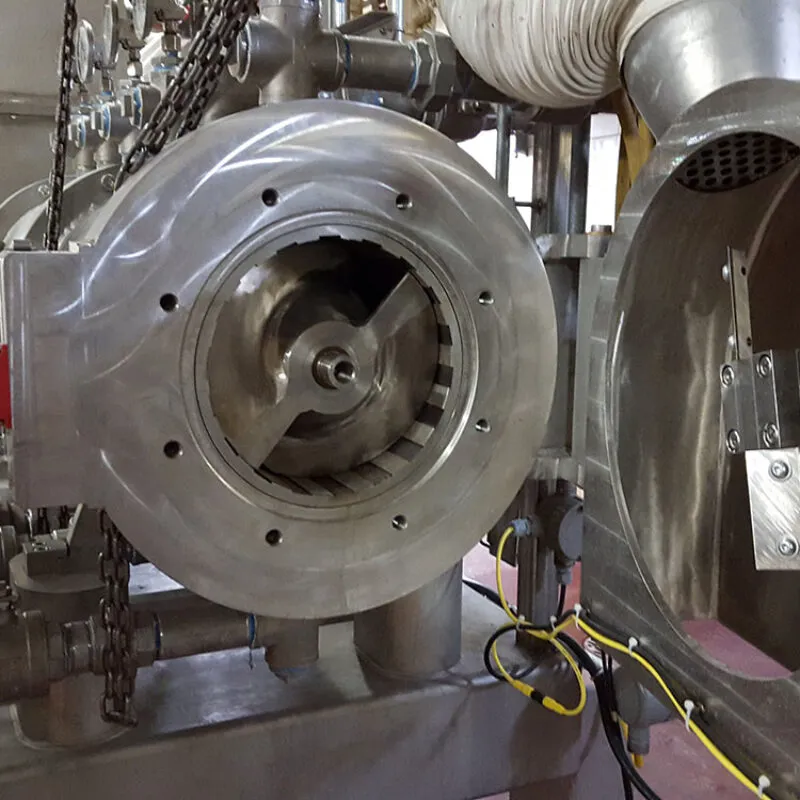

Check out the video below to see a Bonnot plastic extrusion machine in action.