July 18, 2025

An Introduction to Single Screw Extruders

Explore the basics of single screw extruders—how they work, core components, advantages, and common manufacturing applications.

20th December 2018

To put it simply, just about anything. Extruders are a key component of the manufacturing process, so when combined with feeding, cutting, de-airing and other forms of equipment, they can create everything from pet treats to hydrocolloid used for colonoscopy bags. Let’s explore the most common types of extruder machines and the industries they can serve.

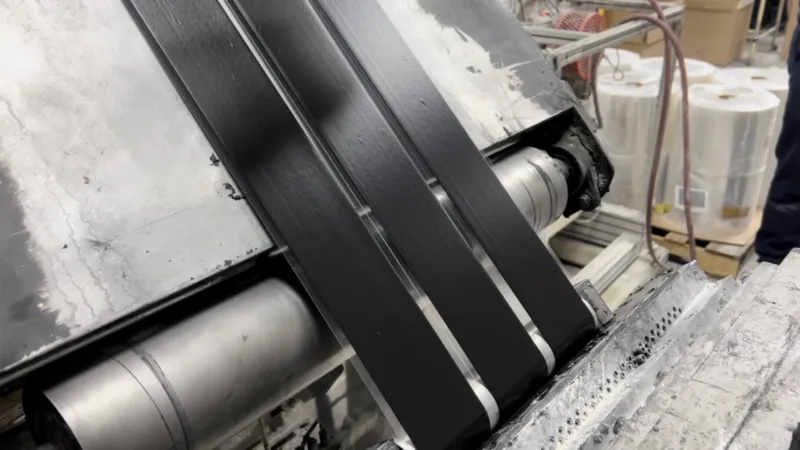

Manufacturers who process materials like rubber bales, silicone and EPDM know that breaking them down is the hardest part of the job. These materials generally come in large quantities and, due to their stickiness, require special chemicals or talc to be formed into manageable sizes and consistencies. It’s a messy, labor-intensive process that can be streamlined with a Bonnot Company rubber bale feeder and rubber extruder.

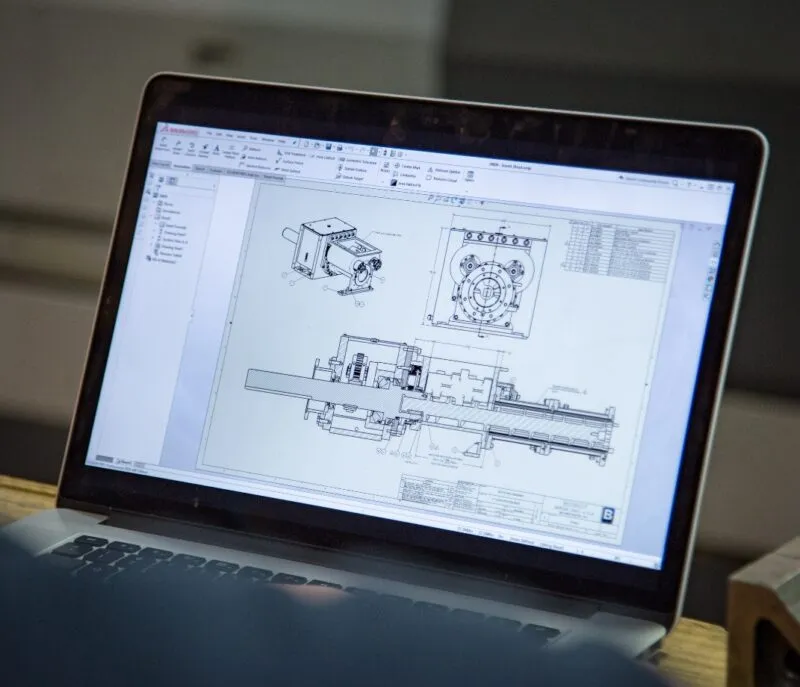

The feeder equipment can be mounted to compounding types of extruders to accommodate a variety of standard bale and output sizes. Through collaboration with the Bonnot Company, custom screws can be designed specifically for your machine and manufacturing needs to improve process control. Even if your facility has tight space constraints, we can create a compact solution to meet your needs and optimize production.

In the cereal, snack and pet food industries, it’s essential that a high volume of consistent products is created with the highest safety and efficiency standards. Types of extruders designed for cooking and cooling foods have helped streamline the food production process in countless ways. For example, food extruder machines from the Bonnot Company eliminate batch cooking by consistently cooking semi-moist, moist, dry and pre-mixed foods with a high level of temperature, pressure and timing precision. When combined with custom extrusion dies and extrusion cutters, the same machine can be used to create a nearly unlimited variety of food pellet shapes and sizes. In terms of safety and longevity, Bonnot Company food extruders are made with stainless steel liners to ensure sanitary production and less downtime for replacement parts.

Certain types of extruder machines only need to produce small batches of materials, such as those used in R&D testing departments across industries. These smaller extruders can be table mounted or fixed to a mobile or custom base to meet the needs of any lab space or facility layout.

The Bonnot Company’s lab extruders are often used to create activated carbon for air and water purification. They have a wide range of part shapes and sizes, including auger, barrel, screw and die configurations. Depending on your lab’s needs, stainless steel and carbon steel construction options are available. With Bonnot, the potential for customization is almost limitless.

From refining crude materials to changing molecular structure, catalysts are a crucial part of many production processes. With the Bonnot Company’s over 50 years of experience in catalyst production, you can rest assured that our catalyst extruders are up to the task.

The types of extruders Bonnot offers the catalyst industry are unmatched in their level of customization. Our extruder models are available in benchtop sizes, as well as the standard 4″, 6″ and 8″ sizes for high volume production. Jacketed barrels can be designed for specified heating and cooling requirements, along with custom auger and barrel dimensions. But no matter the level of customization, the final product will feature the simplicity of Bonnot’s proprietary designs to help sustain operational requirements and meet and even exceed peak load specifications.

At the Bonnot Company, understanding your unique needs and helping you meet and exceed them is our priority. With our industry-leading blend of customization and design simplicity, the types of extruders we can optimize for your facility are nearly endless. For more information on our products, services and extruder testing facilities, contact us today.

July 18, 2025

Explore the basics of single screw extruders—how they work, core components, advantages, and common manufacturing applications.

September 27, 2024

The Bonnot Company has manufactured a line of extruders for processing butyl/mastic rubbers (butyl) since the 1950's. The company recognized the need to offer processing extruders for this rapidly developing market. In keeping with a core principle of continuous improvement, these designs have evolved over time to remain the pre-eminent industry choice for butyl processing equipment/extruders.

September 19, 2024

The Bonnot Company has a variety of custom extruders designed for bulk feeding of rubbers, both natural and synthetic, silicones, butyls and mastics. Regardless of the batch size or material viscosity, there is a solution available. If one of the company's standard designs does not meet your needs, a custom solution is developed. Customized solutions specifically tailored to a customer's needs are a core competency of ours and competitive advantage.