February 19, 2026

An Introduction to Single Screw Extruders

Explore the basics of single screw extruders—how they work, core components, advantages, and common manufacturing applications.

28th May 2019

The Bonnot Company has been in the business of extrusion for over 125 years, so it’s safe to say we’ve been around the block when it comes to creating high-quality machines for a variety of industries and applications. But the extruders themselves aren’t the only things we specialize in — to ensure we can tackle any need, we’ve developed plenty of extrusion cutting machines to work right alongside them. Take a look at some of the extrusion cutting machines we offer and learn which ones might be best suited to your unique needs.

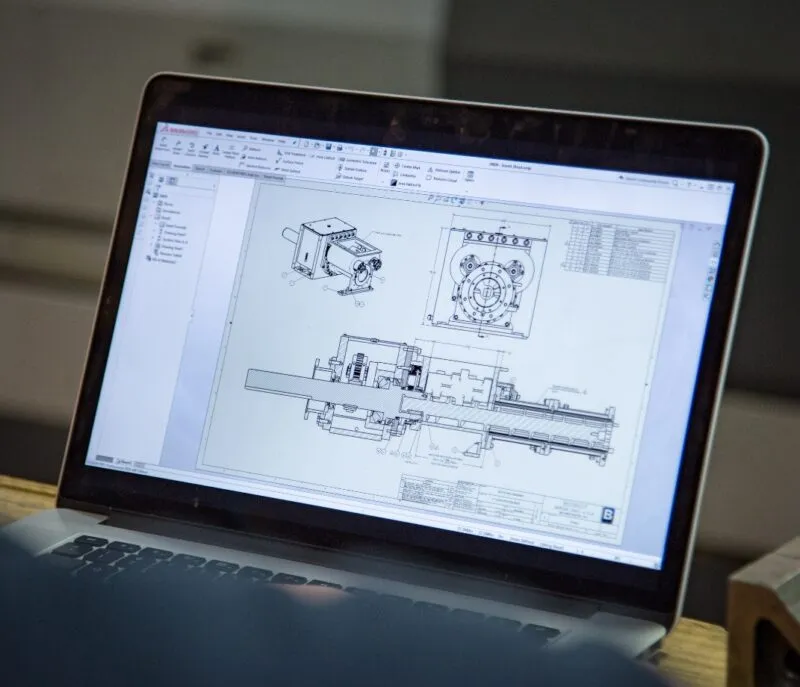

A Bonnot commercial extrusion cutting machine can help enable users to optimize their processing streams and create more consistent final products. While we’re always ready to help our customers create a custom cutting solution focused on their specific application, we do have a few specific categories of machines for material cutting.

Bonnot extruders and cutting equipment are up for just about any challenge, but there are certain industries where our cutters are most frequently used. Any form of pelletizing is where our machines truly shine, helping create consistent shapes and sizes of any material you’re extruding.

Whether you’re extruding cereal, pasta or dog food and treats, a Bonnot food extruder coupled with a rotary die or guillotine cutter will deliver a perfect product every time. Our cutters even work on dry and moist applications, so no matter your product, we can create the ideal system for your needs.

The importance of consistency in catalysts cannot be overstated. A Bonnot extrusion cutting machine can be designed to cut pellets and hollow rings of all thicknesses, keeping a tight tolerance on the cut of the material. To ensure our machines work exactly as you need them to, we have a state-of-the-art testing facility where we can run trials on the rotary, offset rotary or custom cutting solution we’ve developed for you.

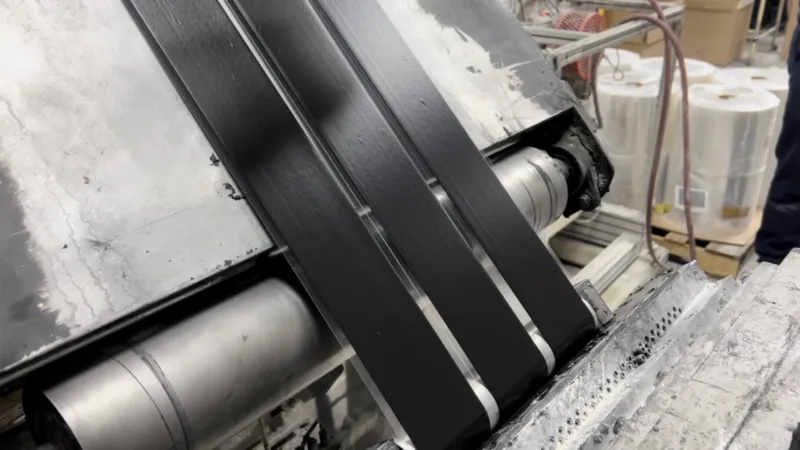

An extrusion cutting machine from Bonnot can even handle abrasive materials like coal and carbon products, earning us the moniker of “brickyard tough.” Our robust machinery is designed to process the toughest materials in most cost-effective way possible, which includes not just efficient cutting, but less downtime for maintenance and repairs as well.

We’re passionate about a lot of things at the Bonnot Company, but creating and testing a custom cutter to meet the unique demands of an ever-broadening range of industries is one of our biggest. Find out how we can address the challenges you face and the standards you strive for by contacting our experts or requesting a custom quote today.

February 19, 2026

Explore the basics of single screw extruders—how they work, core components, advantages, and common manufacturing applications.

September 27, 2024

The Bonnot Company has manufactured a line of extruders for processing butyl/mastic rubbers (butyl) since the 1950's. The company recognized the need to offer processing extruders for this rapidly developing market. In keeping with a core principle of continuous improvement, these designs have evolved over time to remain the pre-eminent industry choice for butyl processing equipment/extruders.

September 19, 2024

The Bonnot Company has a variety of custom extruders designed for bulk feeding of rubbers, both natural and synthetic, silicones, butyls and mastics. Regardless of the batch size or material viscosity, there is a solution available. If one of the company's standard designs does not meet your needs, a custom solution is developed. Customized solutions specifically tailored to a customer's needs are a core competency of ours and competitive advantage.