July 14, 2025

An Introduction to Single Screw Extruders

Explore the basics of single screw extruders—how they work, core components, advantages, and common manufacturing applications.

30th January 2019

The size and shape of catalysts can have a major effect on how much activity they produce and how effective they are at their jobs overall. Particle size, in particular, can increase activity or create pressure drops, which can not only affect the outcome of the reaction but they also can affect your bottom line. Catalyst production can be costly, so creating the best possible product every time is a must.

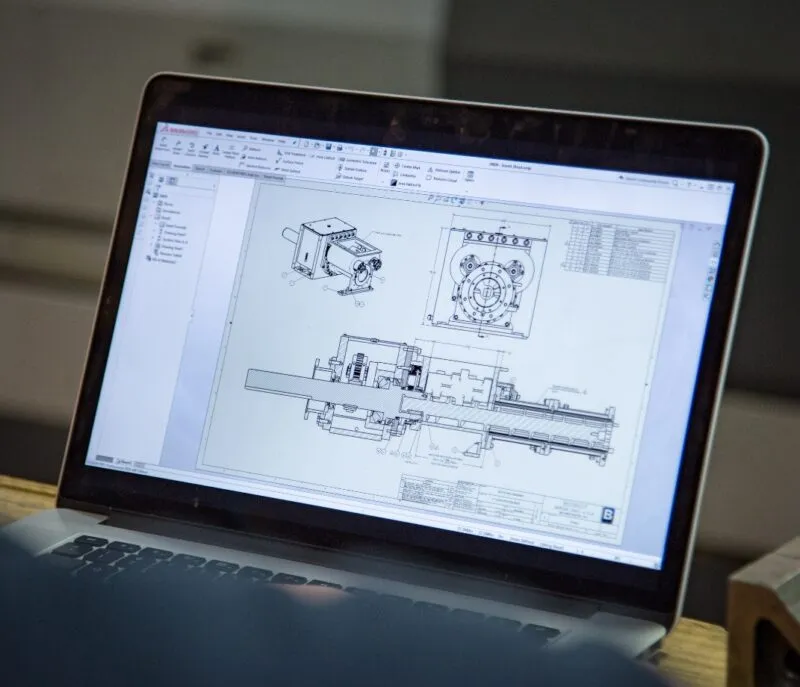

The Bonnot Company’s catalyst extruders are custom engineered for your unique needs, meaning they can produce pellets as small as 1/32″ or even rod-shaped catalysts. Our dies can produce supported or unsupported rings, hollow or solid rods and virtually any other shape you require to get the job done. Bonnot’s extruders also come in a variety of sizes, so whether you need a benchtop apparatus that can be transferred from one part of your facility to the next or an 8″ extruder for high volume production, we can make it happen.

Catalyst production generally begins with a paste or slurry of your desired substance. When extruding catalysts, the next steps involve the paste being forced through a die plate or pelletizer to form your desired shapes and sizes. However, if the paste is too viscous, it can create blockages within the extruder. On the other hand, if the paste is not viscous enough, your catalysts may be unstable and unfit for use.

No matter how unique your catalyst’s rheology is, the Bonnot Company can help you create a custom extruder to ensure you get a functional, consistent formation each time. Contrary to what you might think, our proprietary extruder designs are simple and streamlined — which is exactly why they’re suited for unique specifications. In addition, their modular construction features heavy duty stainless steel and other special alloys that are abrasion and corrosion resistant. When you choose a Bonnot extruder, you’re also choosing to save time and funds on maintenance and repairs: a great choice that will help lead you to a more reliable production schedule and uniform catalyst structure.

Catalyst manufacturing can be costly and time consuming, but when you create, test and implement Bonnot extruders in your facility, you’re sure to achieve your performance goals. To learn more about our products and how you can make use of our extruder testing facilities, contact us today.

July 14, 2025

Explore the basics of single screw extruders—how they work, core components, advantages, and common manufacturing applications.

September 27, 2024

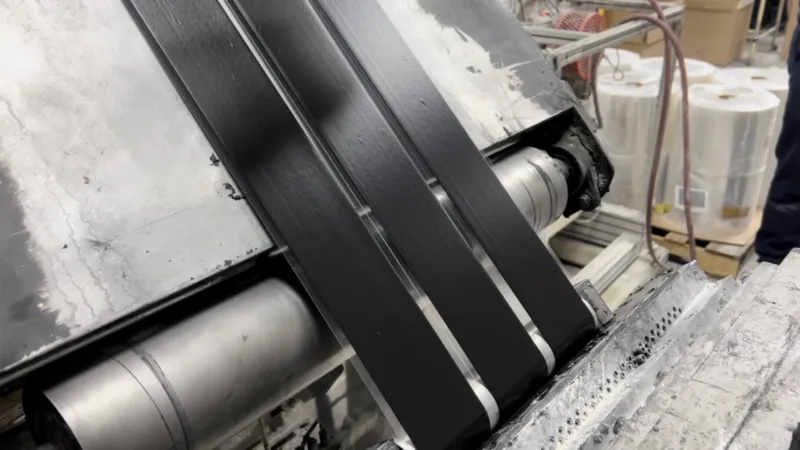

The Bonnot Company has manufactured a line of extruders for processing butyl/mastic rubbers (butyl) since the 1950's. The company recognized the need to offer processing extruders for this rapidly developing market. In keeping with a core principle of continuous improvement, these designs have evolved over time to remain the pre-eminent industry choice for butyl processing equipment/extruders.

September 19, 2024

The Bonnot Company has a variety of custom extruders designed for bulk feeding of rubbers, both natural and synthetic, silicones, butyls and mastics. Regardless of the batch size or material viscosity, there is a solution available. If one of the company's standard designs does not meet your needs, a custom solution is developed. Customized solutions specifically tailored to a customer's needs are a core competency of ours and competitive advantage.