February 12, 2026

An Introduction to Single Screw Extruders

Explore the basics of single screw extruders—how they work, core components, advantages, and common manufacturing applications.

22nd July 2019

Benchtop extruders, also known as laboratory extruders, are used across industries for a wide variety of purposes. The Bonnot Company has been helping labs and testing facilities create custom machines for decades — with so many different needs to fill, benchtop extruders aren’t a one-size-fits-all solution. Our custom-built lab extruders have helped countless clients complete highly specific jobs and push the limits of innovation in their industries. What we’ve listed here are just a few of the many applications for benchtop extruders.

The development and testing phase of creating new products is all about trial and error. Benchtop extruders allow R&D scientists to test out prototypes by making a few samples at a time until they find the ideal formula for their new product, whether it be food, plastic components, soap, pharmaceuticals or something completely different. Because Bonnot develops custom laboratory extruders to meet your specific needs, you can also dramatically reduce the amount of time spent on research and testing, allowing you to get your products on the market and earn profit faster than ever before.

Quality control is crucial whether you’re in the testing phase or manufacturing your product in full swing. Benchtop extruders are ideal for low-volume production, allowing you to set a higher standard of quality without severely impacting your production schedule. Bonnot lab extruders are also robustly built and offer complete data tracking to give you all the benchmarks necessary for success.

One of the biggest benefits of benchtop extruders is, ironically, that they’re small in size. Having a lab scale extruder that can perform virtually all the same functions as a full-sized model provides students and trainees the valuable opportunity to work hands-on with high-quality lab equipment. The fast changeover capabilities of lab extruders let scientists and teachers maximize training time and evaluate results. It also takes up far less physical space, leaving plenty of room for other lab activities surrounding the machine.

No matter the application, the Bonnot Company is ready and eager to help you develop a custom benchtop extruder solution at our R&D testing facility and beyond. Whether you need a single screw or twin screw extruder, an application for the rubber or catalyst industry or another special requirement, we can bring your ideas (and ideals) to life. Contact us today to discuss how we can help.

February 12, 2026

Explore the basics of single screw extruders—how they work, core components, advantages, and common manufacturing applications.

September 27, 2024

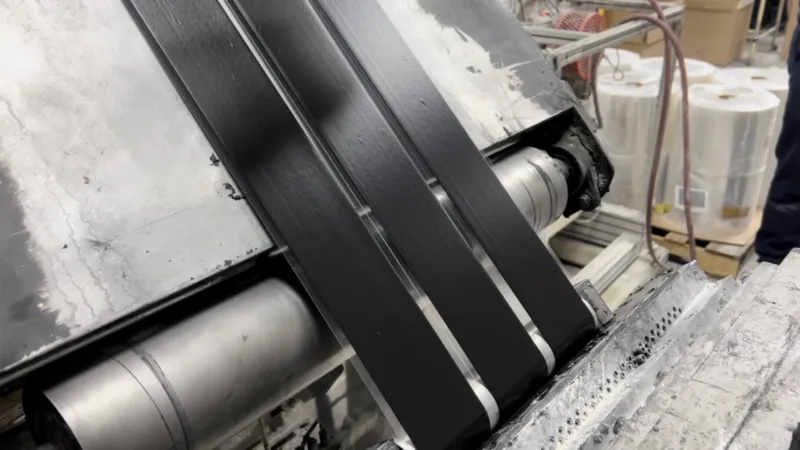

The Bonnot Company has manufactured a line of extruders for processing butyl/mastic rubbers (butyl) since the 1950's. The company recognized the need to offer processing extruders for this rapidly developing market. In keeping with a core principle of continuous improvement, these designs have evolved over time to remain the pre-eminent industry choice for butyl processing equipment/extruders.

September 19, 2024

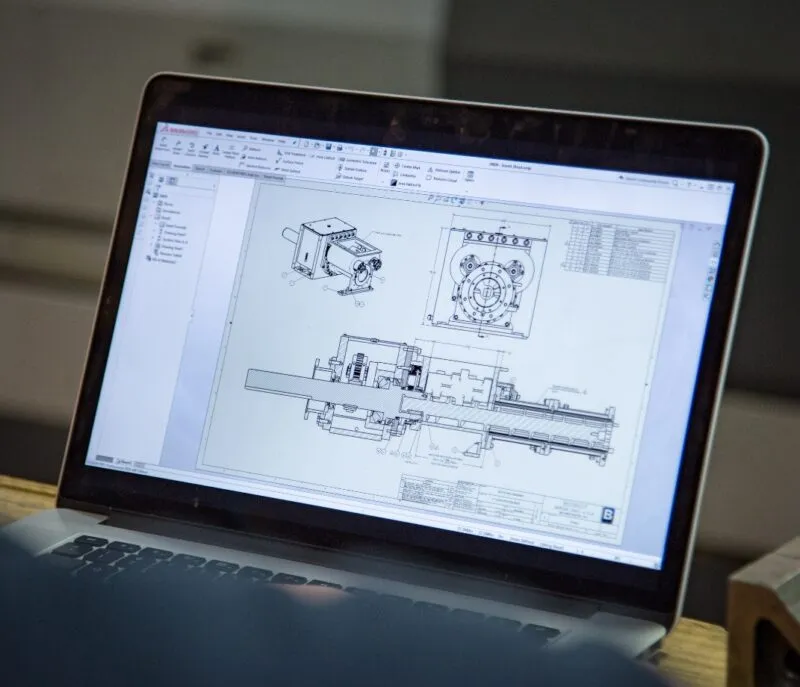

The Bonnot Company has a variety of custom extruders designed for bulk feeding of rubbers, both natural and synthetic, silicones, butyls and mastics. Regardless of the batch size or material viscosity, there is a solution available. If one of the company's standard designs does not meet your needs, a custom solution is developed. Customized solutions specifically tailored to a customer's needs are a core competency of ours and competitive advantage.