February 23, 2026

An Introduction to Single Screw Extruders

Explore the basics of single screw extruders—how they work, core components, advantages, and common manufacturing applications.

15th February 2019

AKRON, OH: February 13, 2019 – Bonnot officially launched its new ETP 1 Lab Extruder to an emphatic applause from its customers. The new ETP 1 Lab Extruder provides smooth material ingestion, easy feeding and high versatility; along with quick release components reducing time between trials. The Extruder comes equipped with easy to use, intuitive touch screen controls to effortlessly process countless materials like powders, clay, mastics, catalysts, food stuff and many more. The Extruder is small and compact, but is still robust to handle the toughest processing challenges.

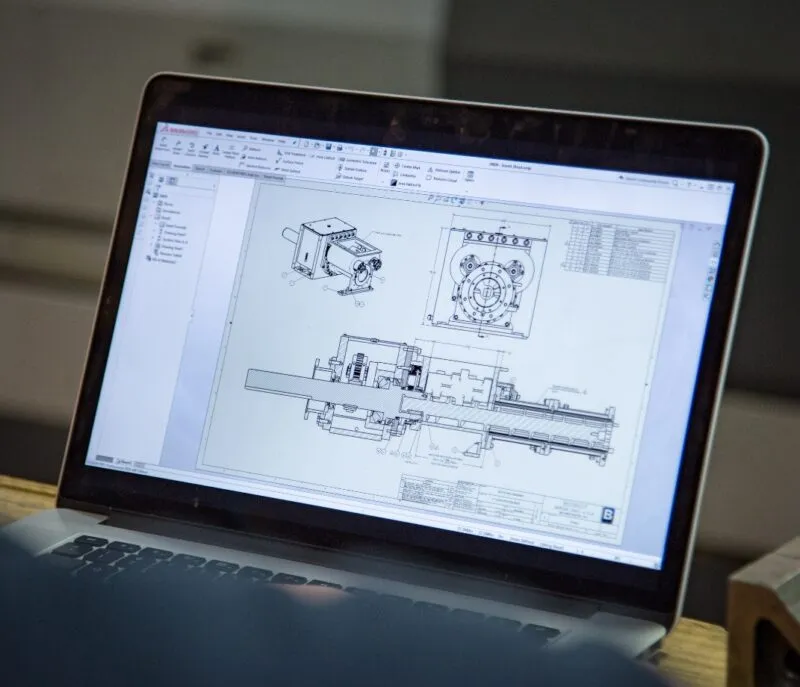

When asked about how the new ETP 1 Lab Extruder will help Bonnot customers George W. Bain III (V.P. of Operations) responded: “The new ETP 1 Lab Extruder will allow customers to easily feed and extrude a diverse group of materials; while precisely controlling and monitoring the process. The extruder is compact, but offers quite a bit of torque for those drier formulations. While the ETP 1 Lab Extruder has some great standard technical features Bonnot can always customize the machine to fit specific needs; such as longer L/D ratio, higher RPM, higher torque, and countless screw geometries. Probably one of the best attributes of the ETP 1 Lab Extruder is its scalability so our customers can mitigate risk as they commercialize new products and processes.”

The ETP 1 Lab Extruder is now available for purchase. Please don’t hesitate to contact Bonnot at info@thebonnotco.com or 330-896-6544 for more information.

The Bonnot Company has excelled in the design, engineering, and manufacturing of exceptional extruders, bulk feeders, custom cutters, and more. Our extrusion equipment allows customers to streamline their processes for increased efficiency, productivity, and reliability. As a global leader in reliable extruding equipment, engineering, and consulting for customers in a variety of industries, Bonnot consistently pursues the most advanced and up-to-date technology available. The years may come and go, but our commitment to our customers remains as strong and powerful as our beginning. With each new idea and innovation in extrusion, we are blazing a new path to a stronger future. While our focus is on the manufacturing of top-of-the-line extruder machines, bulk feeders, and custom cutting machines, we also provide a range of global services including consulting and equipment leasing. No matter what your need for in extrusion, Bonnot is on standby to help.

If you would like more information about this topic, please call George W. Bain III at 330-896-6544, or email gwbain@thebonnotco.com.

February 23, 2026

Explore the basics of single screw extruders—how they work, core components, advantages, and common manufacturing applications.

September 27, 2024

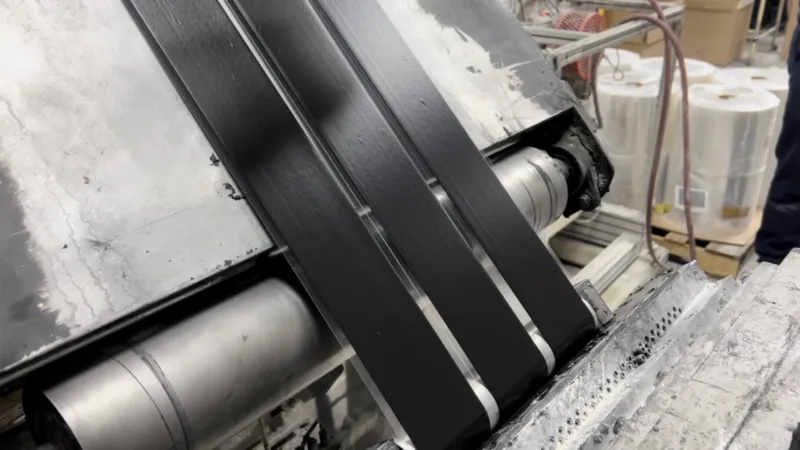

The Bonnot Company has manufactured a line of extruders for processing butyl/mastic rubbers (butyl) since the 1950's. The company recognized the need to offer processing extruders for this rapidly developing market. In keeping with a core principle of continuous improvement, these designs have evolved over time to remain the pre-eminent industry choice for butyl processing equipment/extruders.

September 19, 2024

The Bonnot Company has a variety of custom extruders designed for bulk feeding of rubbers, both natural and synthetic, silicones, butyls and mastics. Regardless of the batch size or material viscosity, there is a solution available. If one of the company's standard designs does not meet your needs, a custom solution is developed. Customized solutions specifically tailored to a customer's needs are a core competency of ours and competitive advantage.