Meeting high-volume production standards while also producing high-quality pelletized products might seem like a lofty goal to achieve. In reality, you only need equipment on your side that can meet your unique specifications. With a pellet extruder machine from the Bonnot Company, you’ll be able to meet your production quotas while turning out more consistent products.

What is Extrusion Pelletizing Used for?

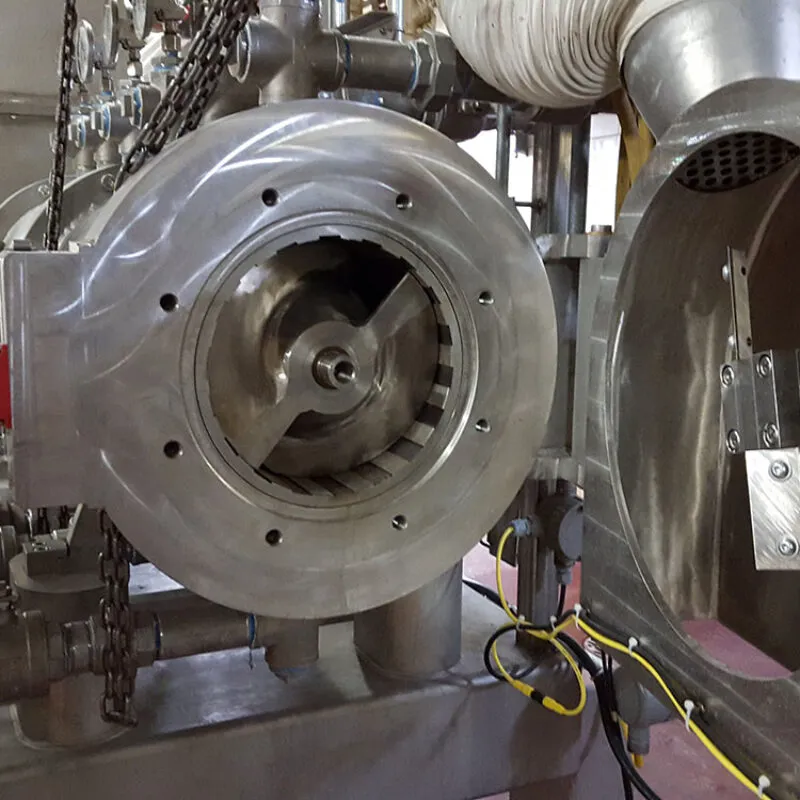

The short answer: just about any strand mixture that you would like to turn into pellets. An extrusion pelletizing machine uses a die and cutter system to form the mixture being pushed through it into pellets. A Bonnot pellet extruder can be outfitted with virtually any die, including custom dies designed precisely for your needs. We also offer a wide selection of auger and barrel configurations to suit your material requirements and output goals, along with heating and cooling options. With such a wide variety of capabilities, pelletizing extruders can be used to create the following products.

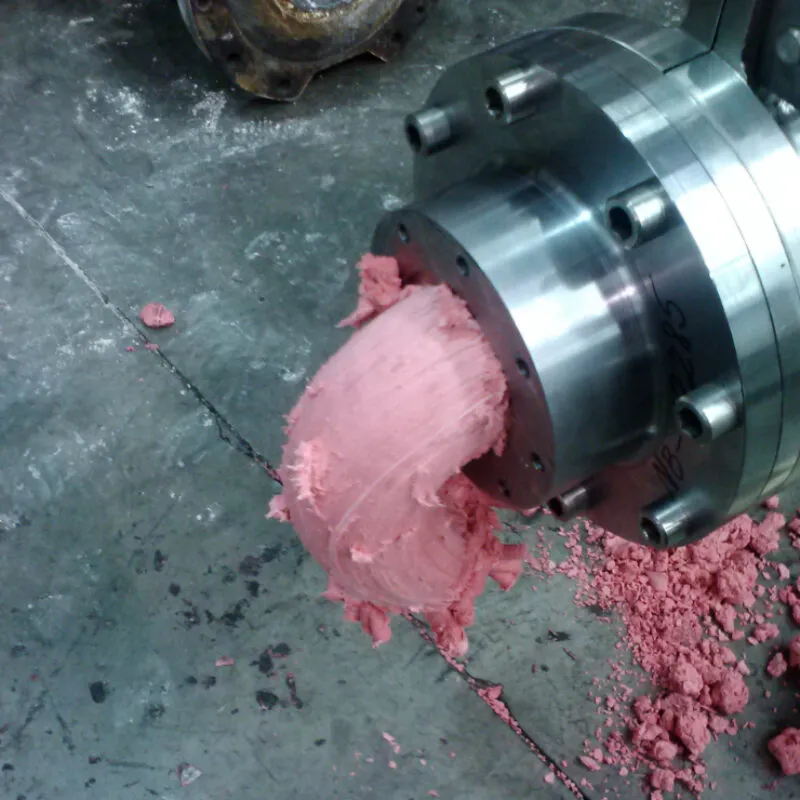

Carbon & Coal

When heated to a certain temperature, carbon fiber and coal products gain plastic-like qualities that make them easy to form and process. Once the pelletizing process is complete, the finished product is ready for use as a fuel source.

Waste streams can also be incorporated into your carbon products to create fuel sources. For example, our machinery can process animal litter, bio-char and more to create viable fuel sources. With a Bonnot extrusion pelletizing machine, your facility will be capable of managing coal and carbon processing with greater efficiency than ever before.