February 4, 2026

An Introduction to Single Screw Extruders

Explore the basics of single screw extruders—how they work, core components, advantages, and common manufacturing applications.

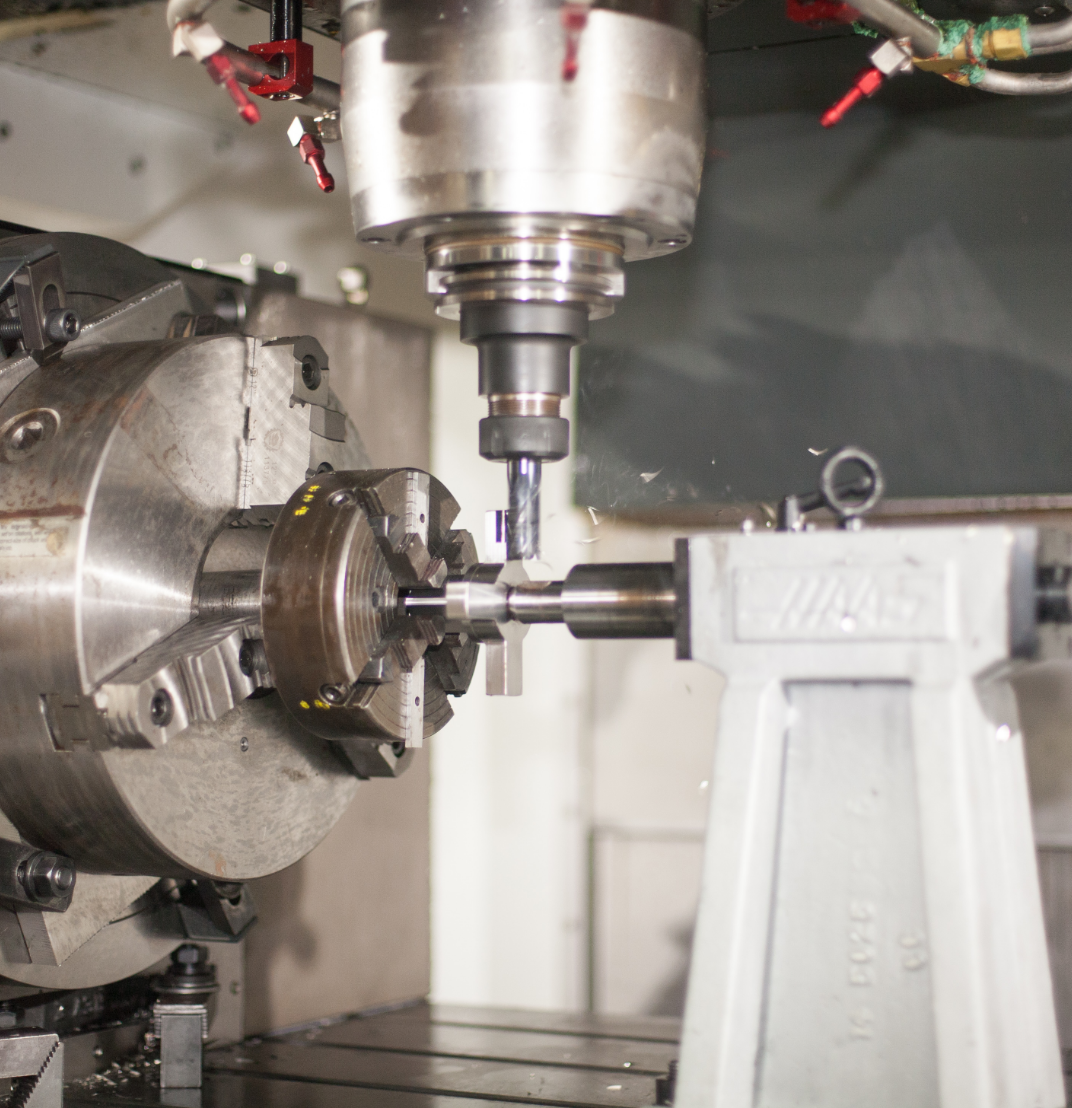

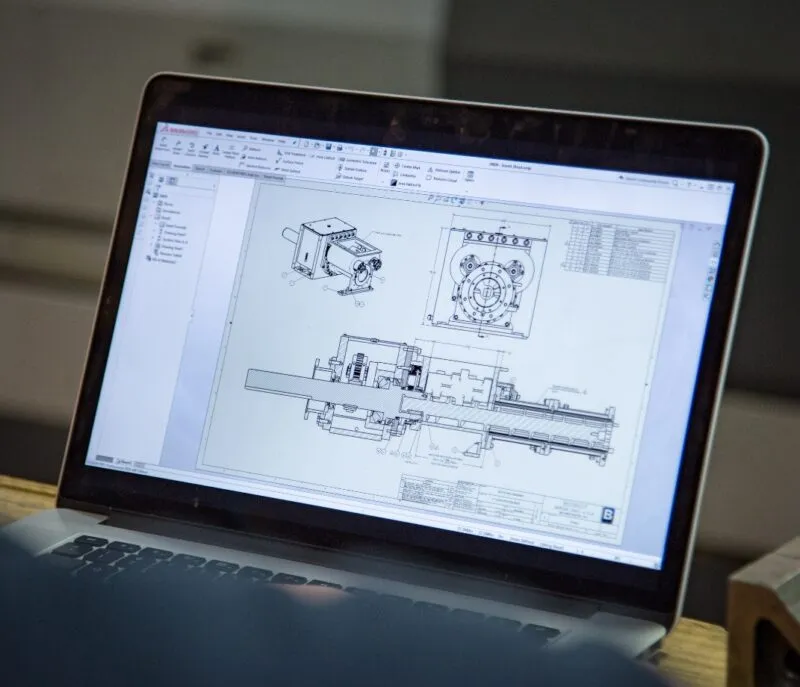

Bonnot machines are built to last. Many are still running after decades of continuous use. But there will always be some parts that need replacing after years of hard work. For high wear, highly abrasive applications, such as chemical catalyst or carbon products, we offer a rebuild program.

Full service operation

Experience in building machines

Cost effective

Here at Bonnot we also specialize in refurbishing and rebuilding our equipment and parts, which means that sometimes a rebuild can be a more cost effective solution. We can return the equipment and parts to original factory condition, and also take this opportunity to improve the design by incorporating newer technology.

This approach can be a more cost effective option for you when you’re looking to increase production. We can work with you to provide a recurring rebuild program that will save you money and reduce downtime.

All bushings and seals are replaced at this time also to return a machine to you ‘as new’. At Bonnot we have full manufacturing capabilities in house, so we can respond to emergencies for all parts in a very quick fashion. Please contact us if we can help you with anything we’ve touched on here…

February 4, 2026

Explore the basics of single screw extruders—how they work, core components, advantages, and common manufacturing applications.

September 27, 2024

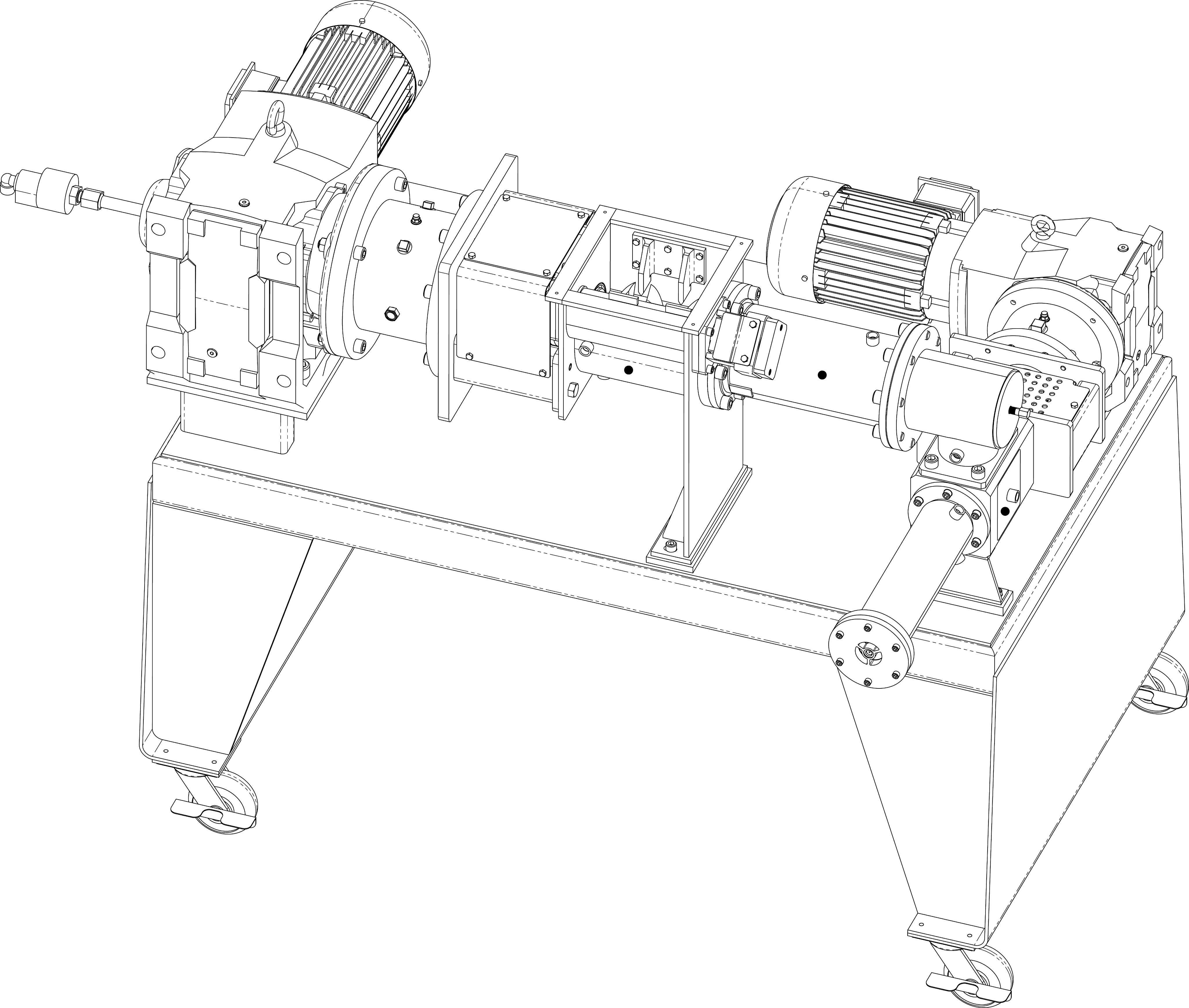

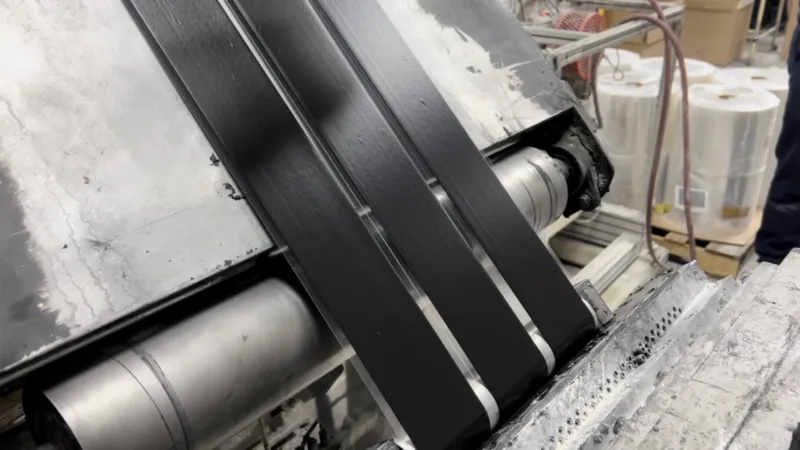

The Bonnot Company has manufactured a line of extruders for processing butyl/mastic rubbers (butyl) since the 1950's. The company recognized the need to offer processing extruders for this rapidly developing market. In keeping with a core principle of continuous improvement, these designs have evolved over time to remain the pre-eminent industry choice for butyl processing equipment/extruders.

September 19, 2024

The Bonnot Company has a variety of custom extruders designed for bulk feeding of rubbers, both natural and synthetic, silicones, butyls and mastics. Regardless of the batch size or material viscosity, there is a solution available. If one of the company's standard designs does not meet your needs, a custom solution is developed. Customized solutions specifically tailored to a customer's needs are a core competency of ours and competitive advantage.