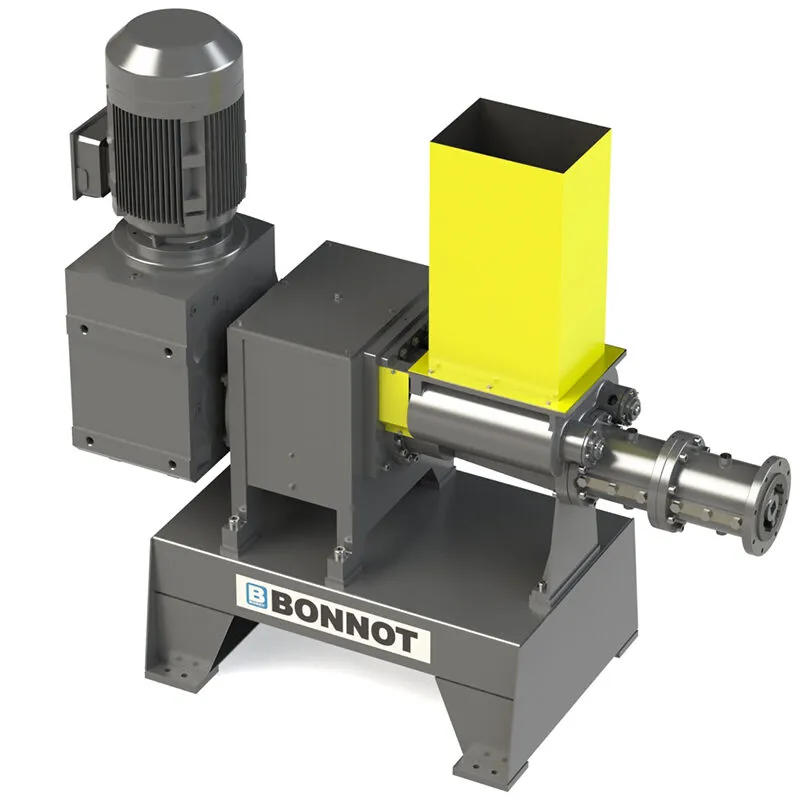

Twin Packer Extruders

The Industry Standard in Single Screw Extrusion

Our most popular design for over 50 years

Bonnot developed the Twin Packer concept to enhance ingestion of difficult materials that are prone to bridging in the feed section.

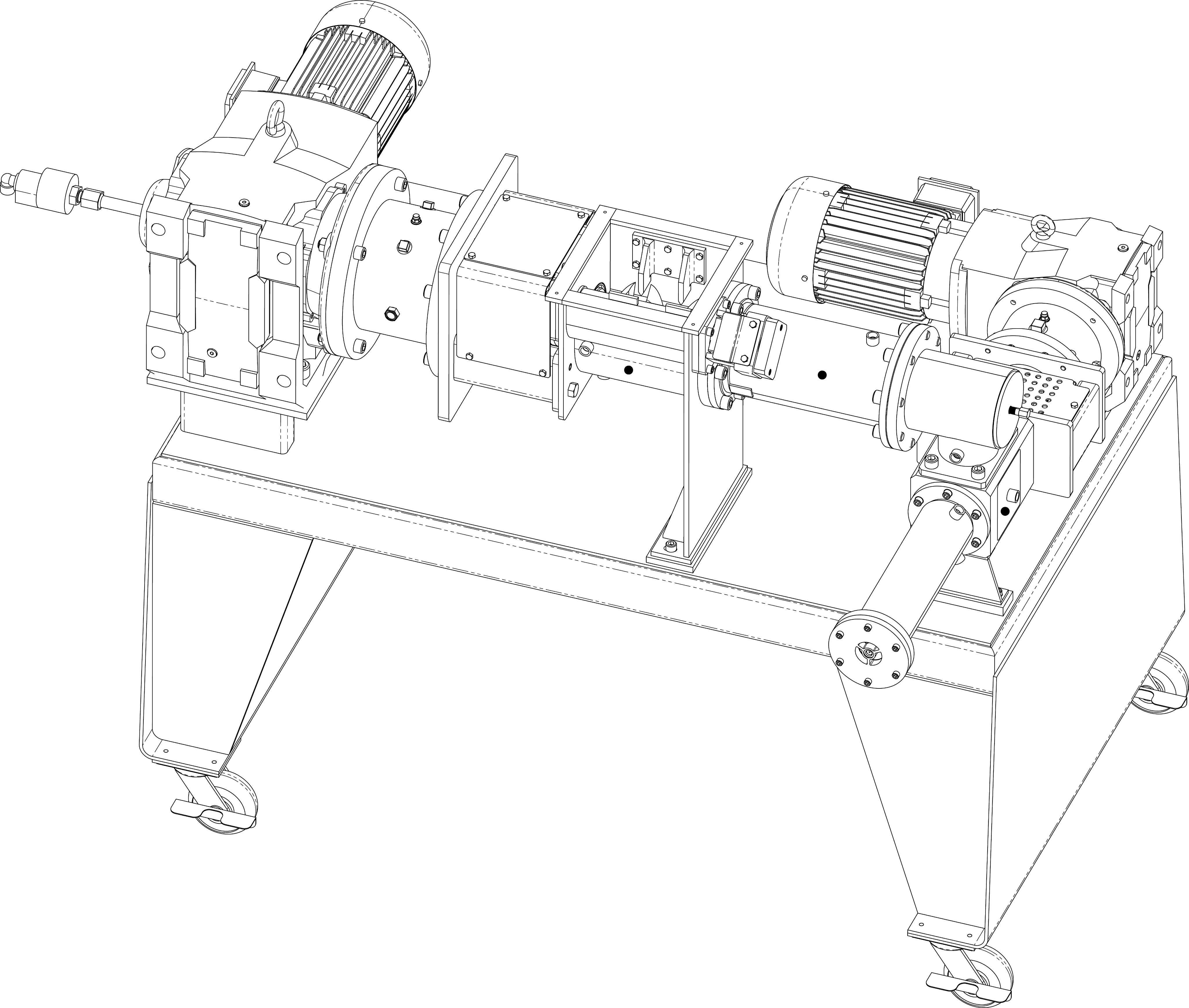

Extruder Design Features

1Twin Packers to Aid Material Ingestion

2Jacketed Barrels for Temperature Control

3Rotary Union for Auger Temperature Control

4High Torque Gear Motor Drive

available in a range of sizes

1 Series TP X

- Output

- 5-15 lbs/hour

- Layout

- 21" x 22" x 16"

- Hopper Opening

- 3” x 2.4”

- Motor Power

- 0.5 HP

- Contact Components

- Customizable

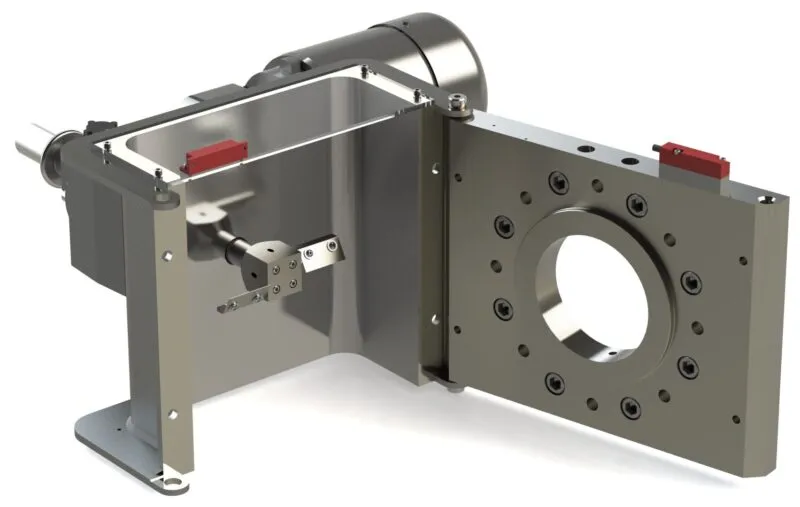

Twin Packers

The twin packers aid material ingestion into the hopper. Packer and hopper dimensions are customizable, in this case they have chrome plating.

Processing Catalyst

The Bonnot Twin Packer extruders are used in a wide range of applications.

Bonnot 2 Series Twin Packer Extruder and Cutter

Want to prove it out?

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.

Get in touch with us