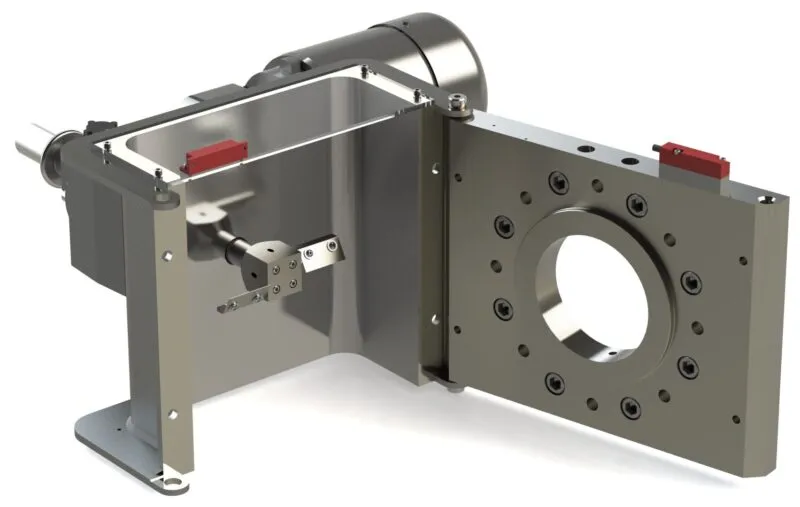

Extruder Design Features

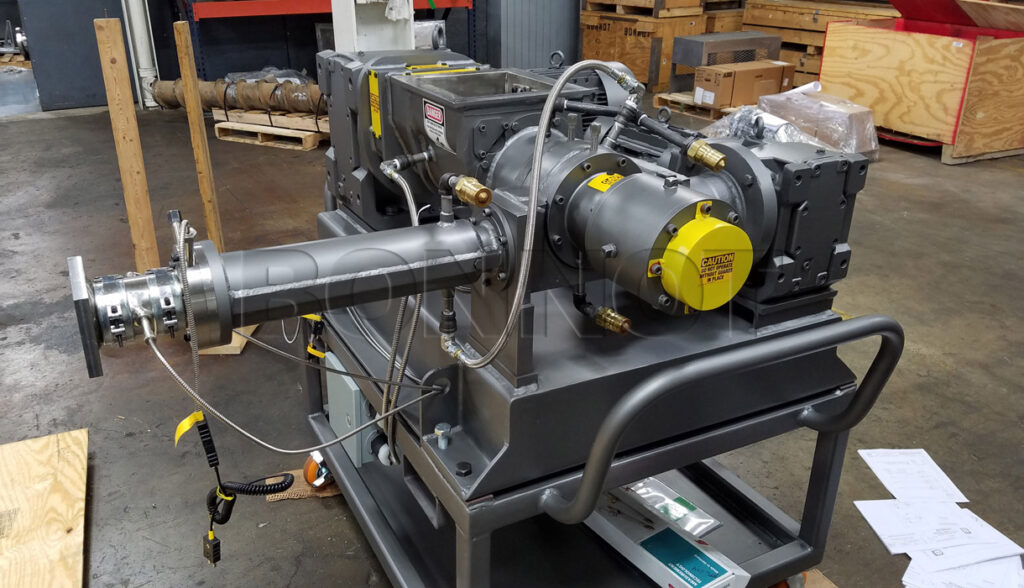

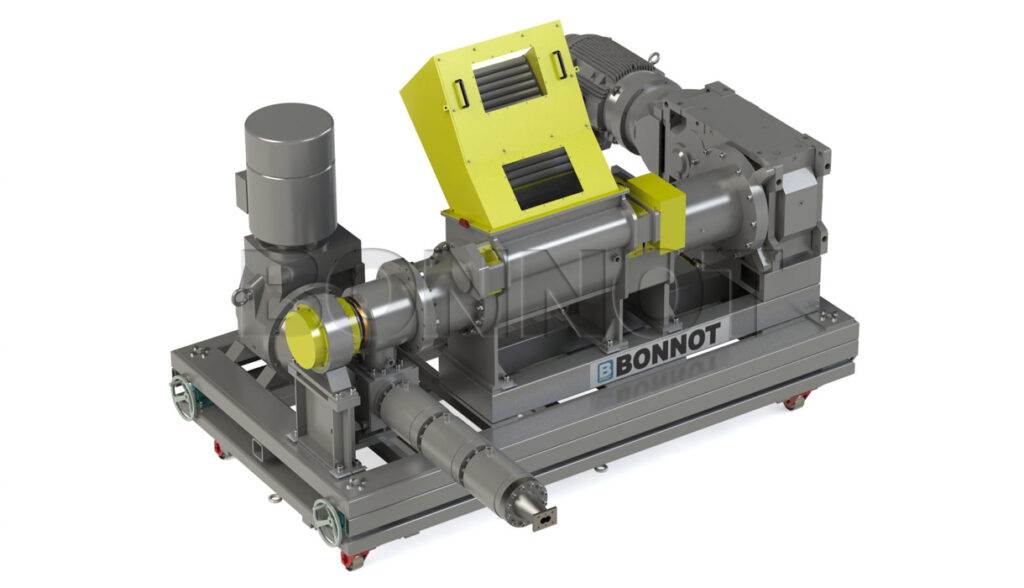

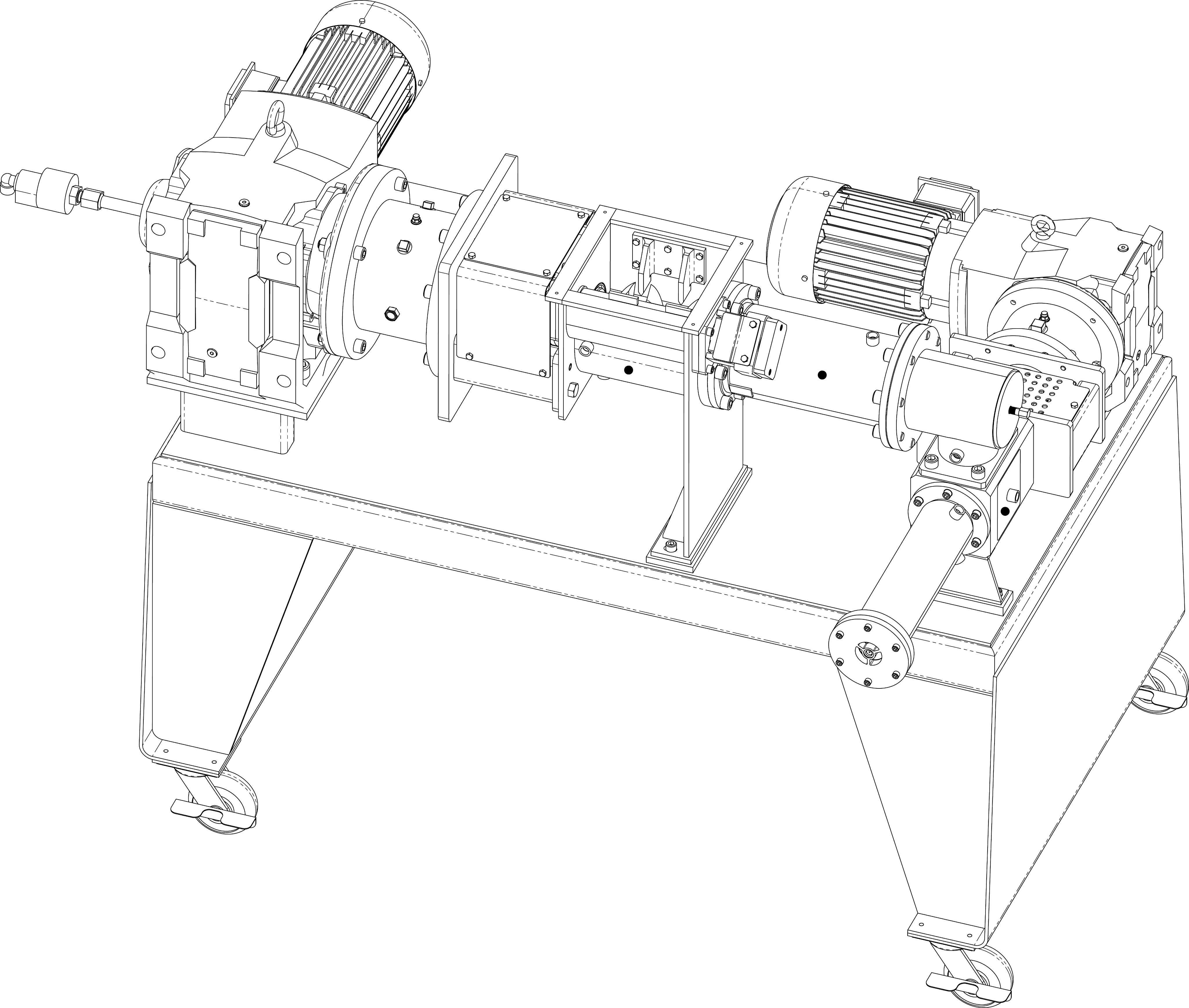

+ Robust carbon steel or stainless steel construction

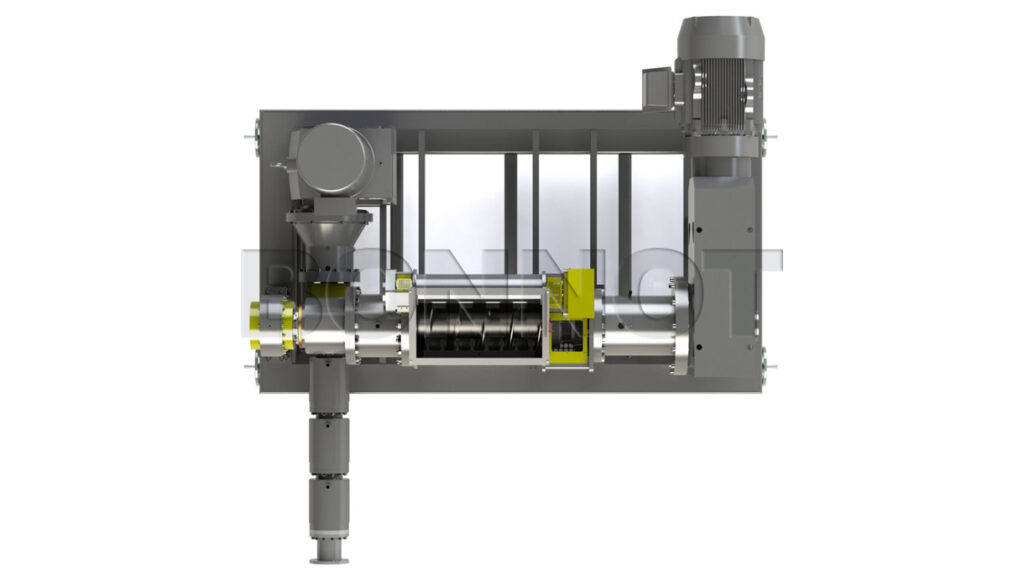

+ Able to accept full bales and process in a controlled fashion

+ Sizes from 2”- 8” (output screw diameter) are available

+ Output metering + or - 5% without a gear pump, for 1% + or - a gear pup

+ Multiple jacketed zones for temperature management

+ Multiple pressure / temperature monitoring locations for control