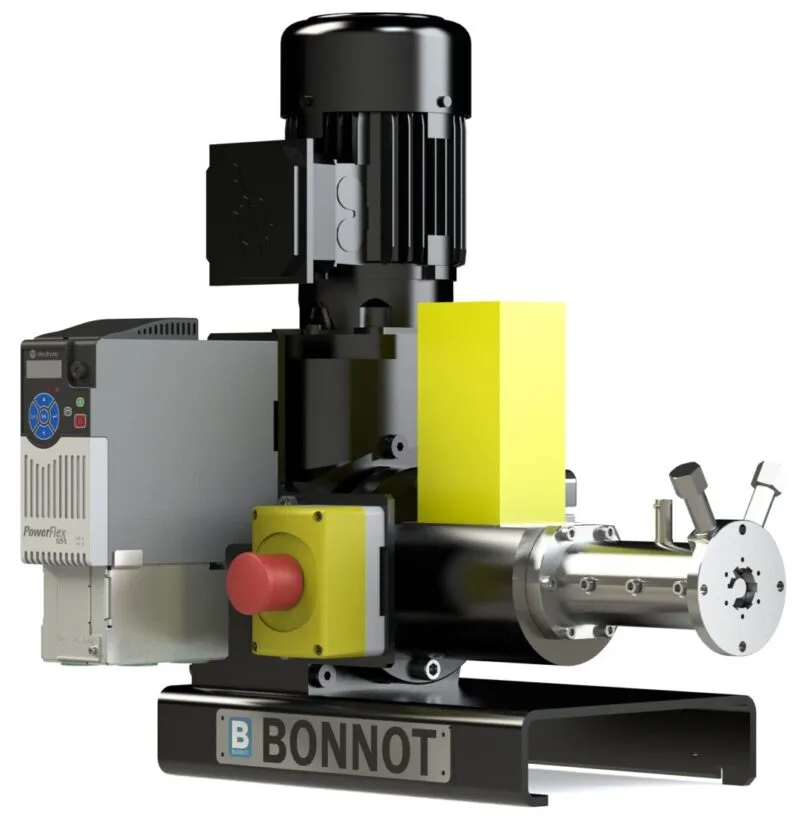

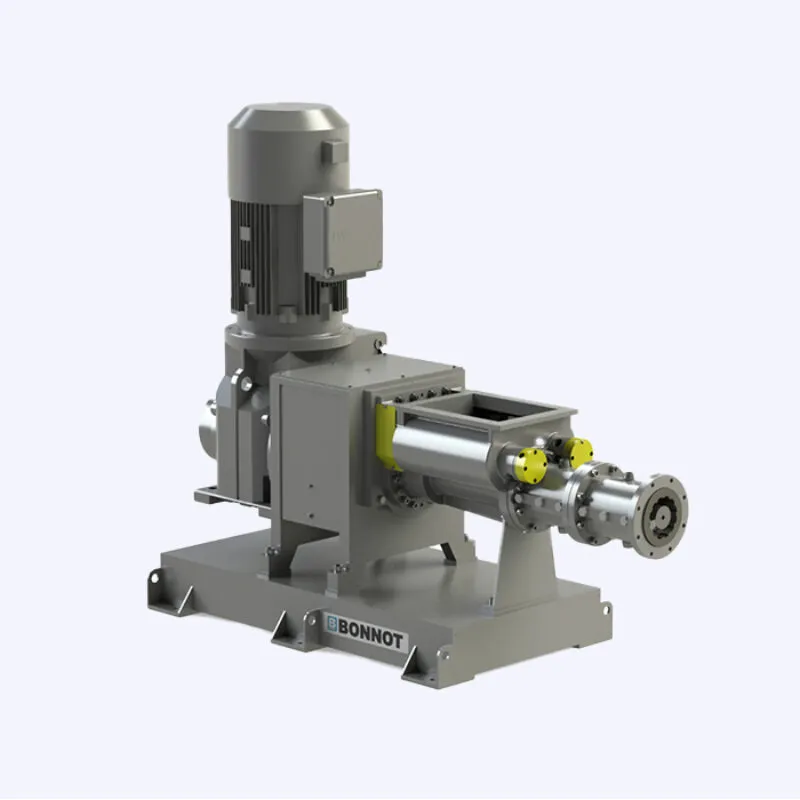

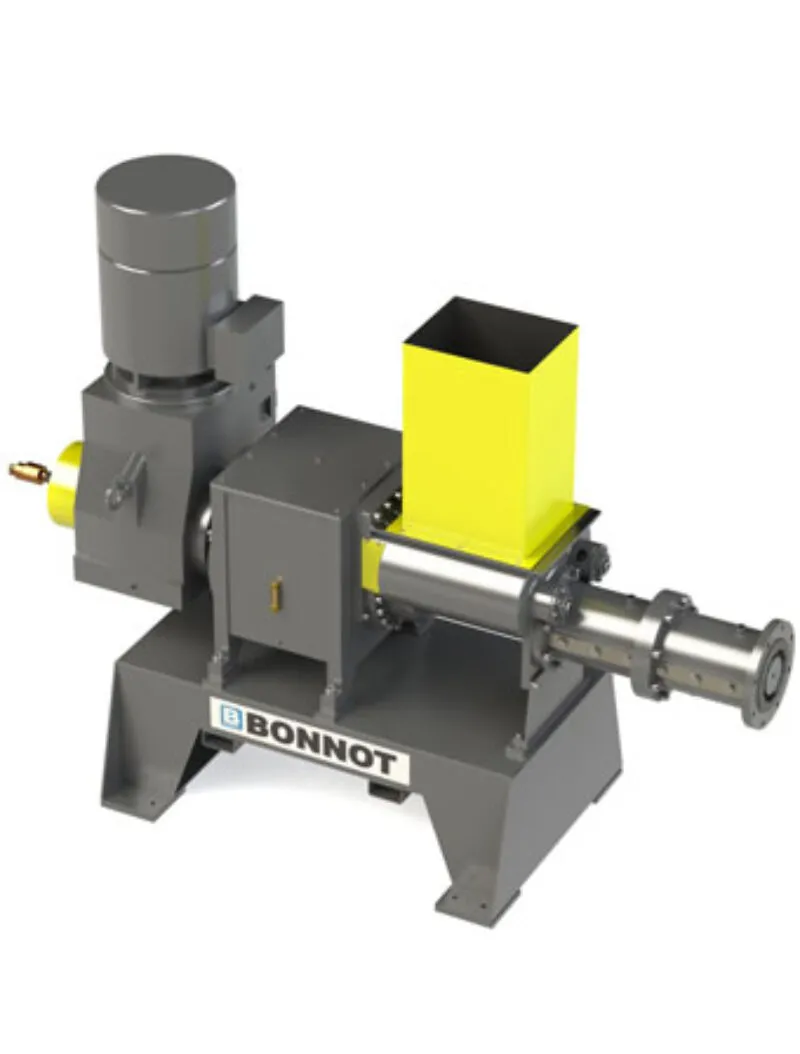

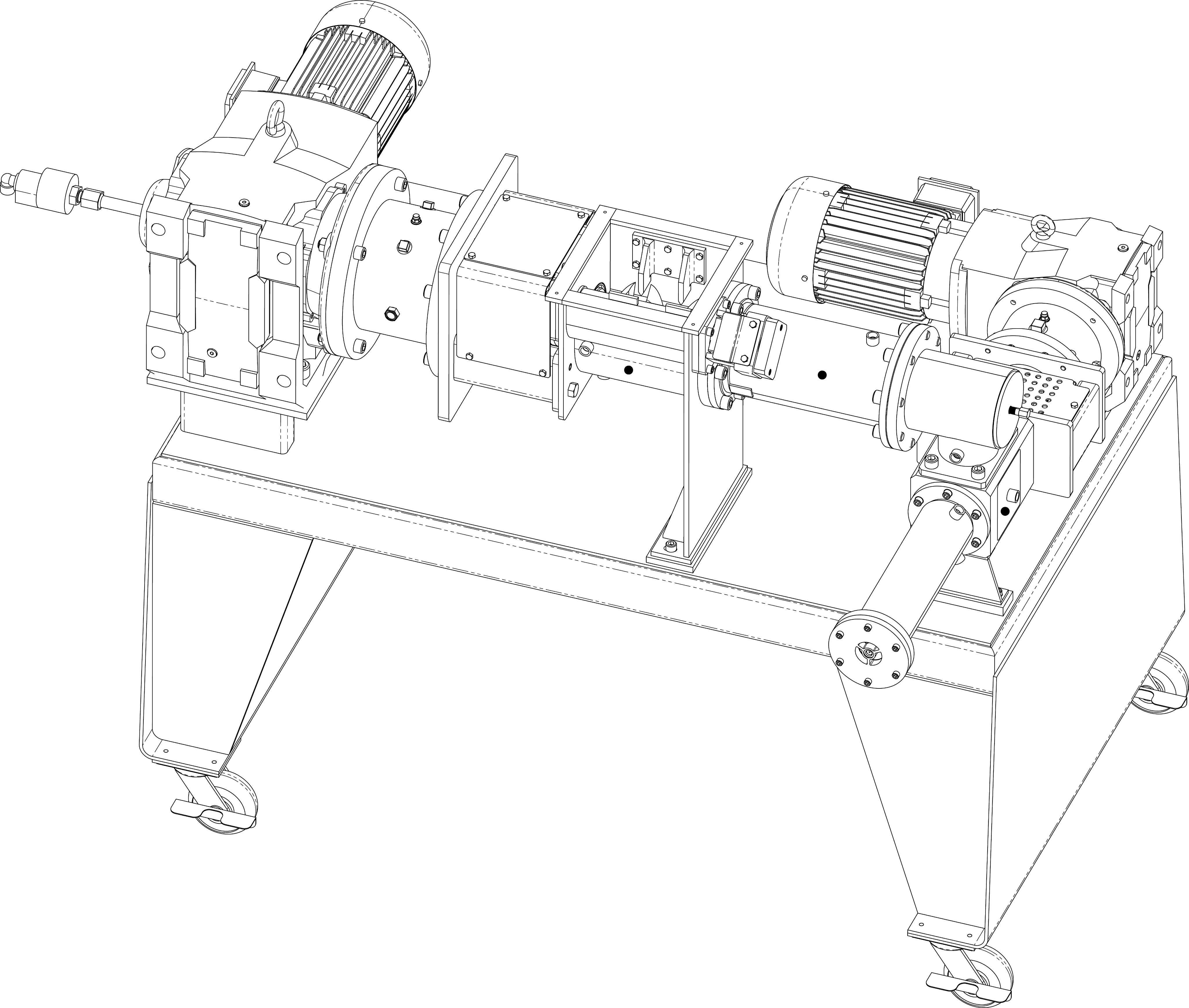

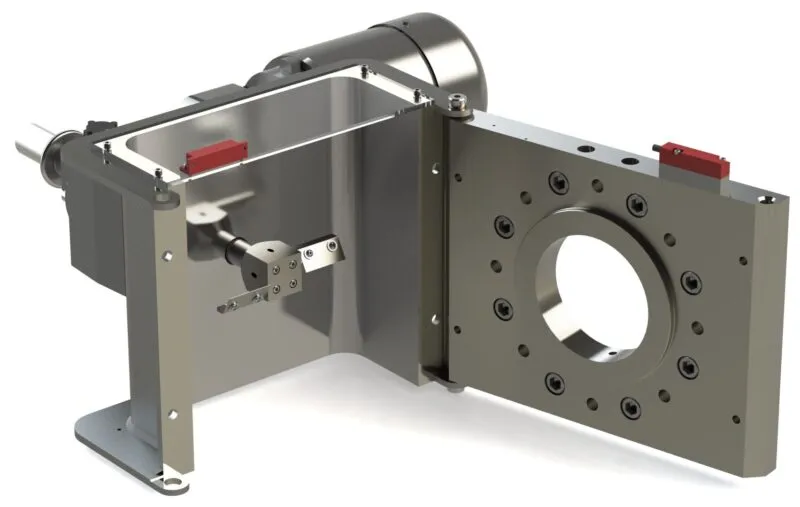

Extruder Design Features

+ Hopper openings dimensioned to accept large batches

+ Counter rotating packer(s) to aid ingestion and prevent “bridging”

+ Hard surfacing and replaceable wear resistant barrel liners

+ Jacketed barrel for temperature processing control

+ Customizable dimensions

+ Configured for your specific application(TCU)