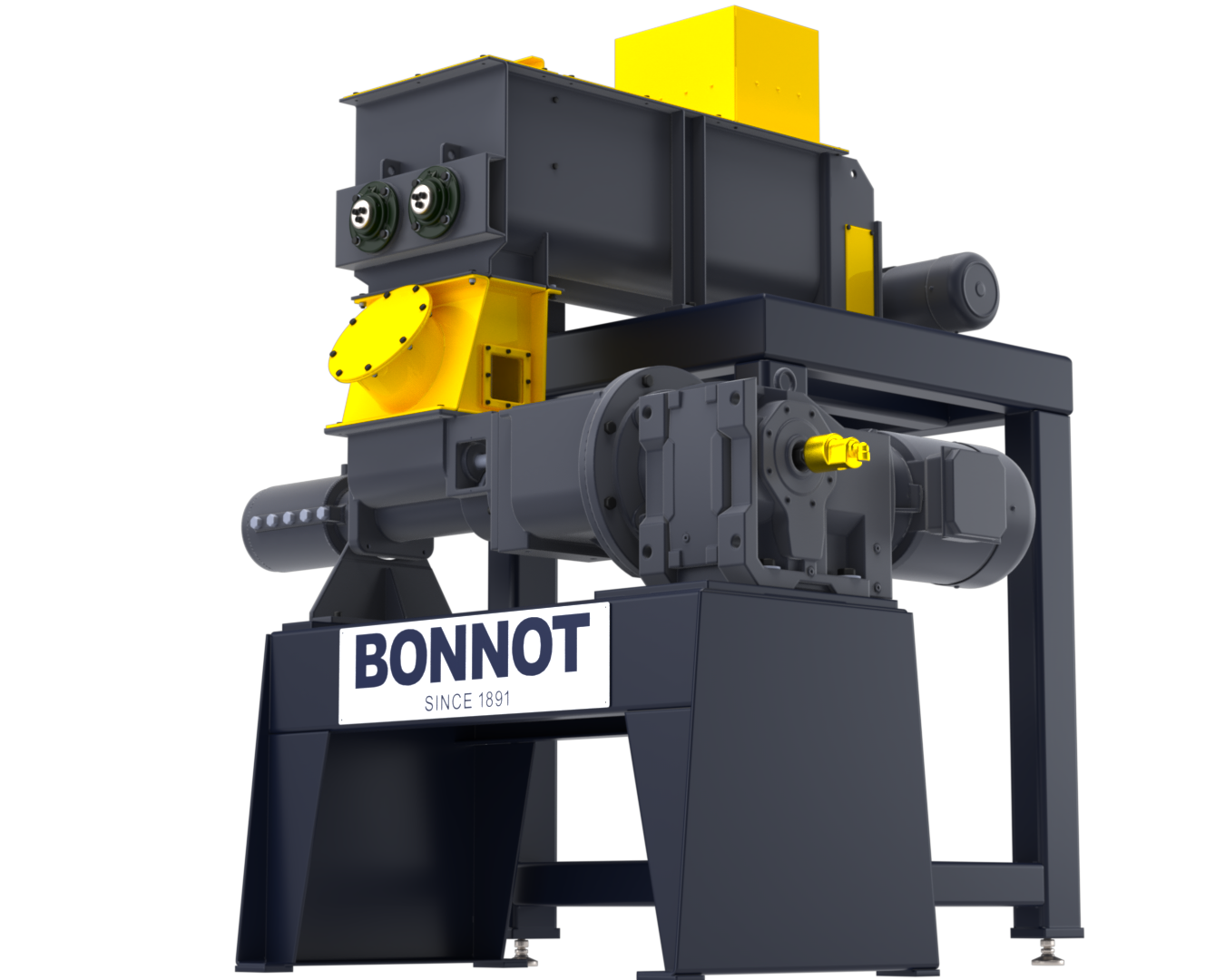

Twin Shaft Feeders

Controlled Feeding for Extrusion or Other Process Equipment

Bonnot developed the Twin Packer concept to enhance ingestion of difficult materials that are prone to bridging in the feed section.

Extruder Design Features

1Twin Shafts for large batch handling

2Variable pitch knives and gate to change residence time and output rate

3Direct Connect Gear Motor

4Custom bases and orientation available to minimize the footprint

5Sealed Gear Case for durability

Specifications

Extruder Standard Specifications

8 Series TF

- Layout

- 55" x 21" x 19"

- Hopper Opening

- 42" x 16"

- Hopper Motor

- 5 HP

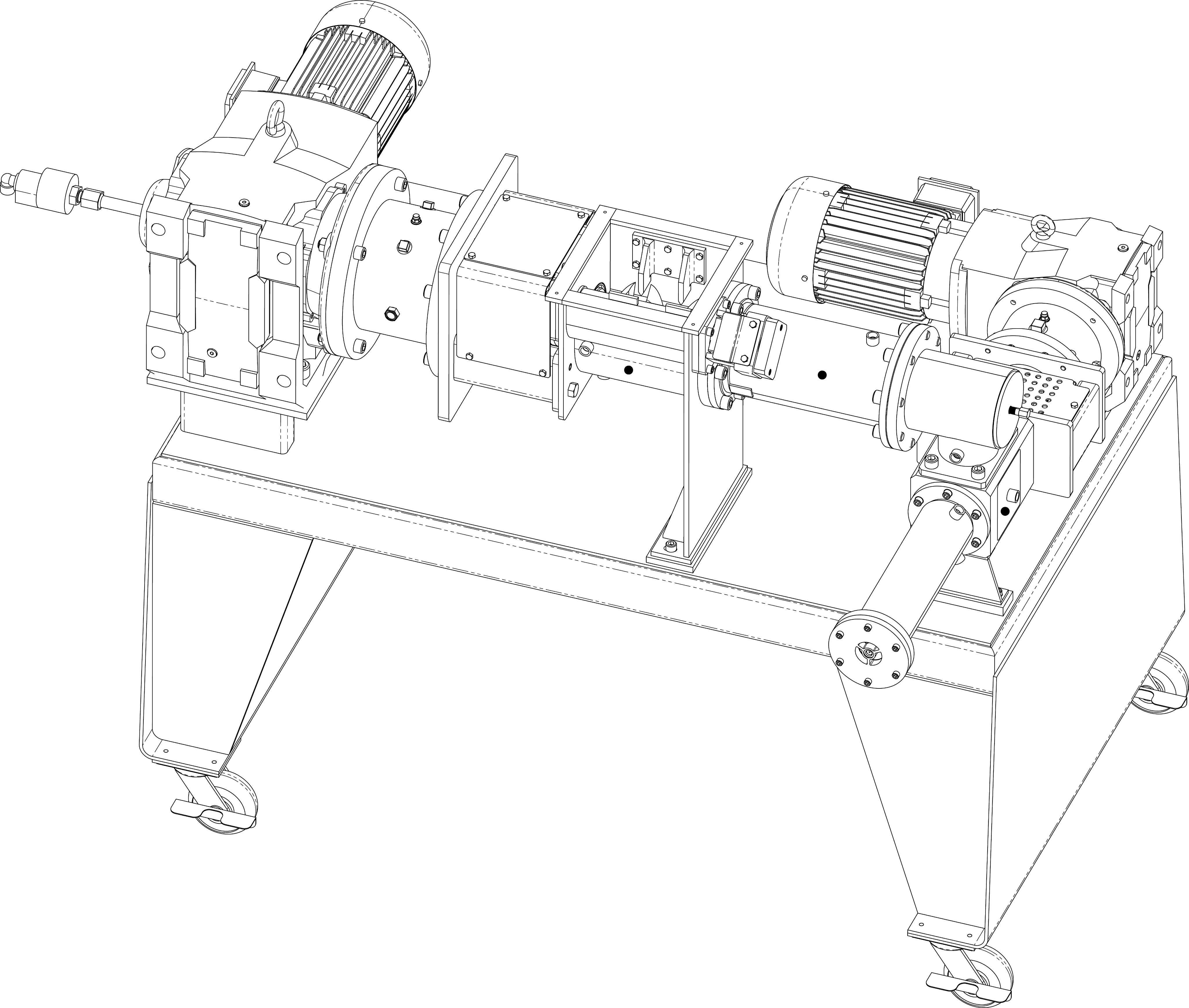

Twin Shafts with Variable Pitch Knives

Bolt through variable pitch knives allow for varying the residence time, shear and mix. Also, easy to replace when worn.

Twin Shaft Feeder Mounted

In typical production environments, our Twin Shaft Feeders are mounted directly above in order to direct feed our extruders.

Want to prove it out?

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.

Get in touch with us