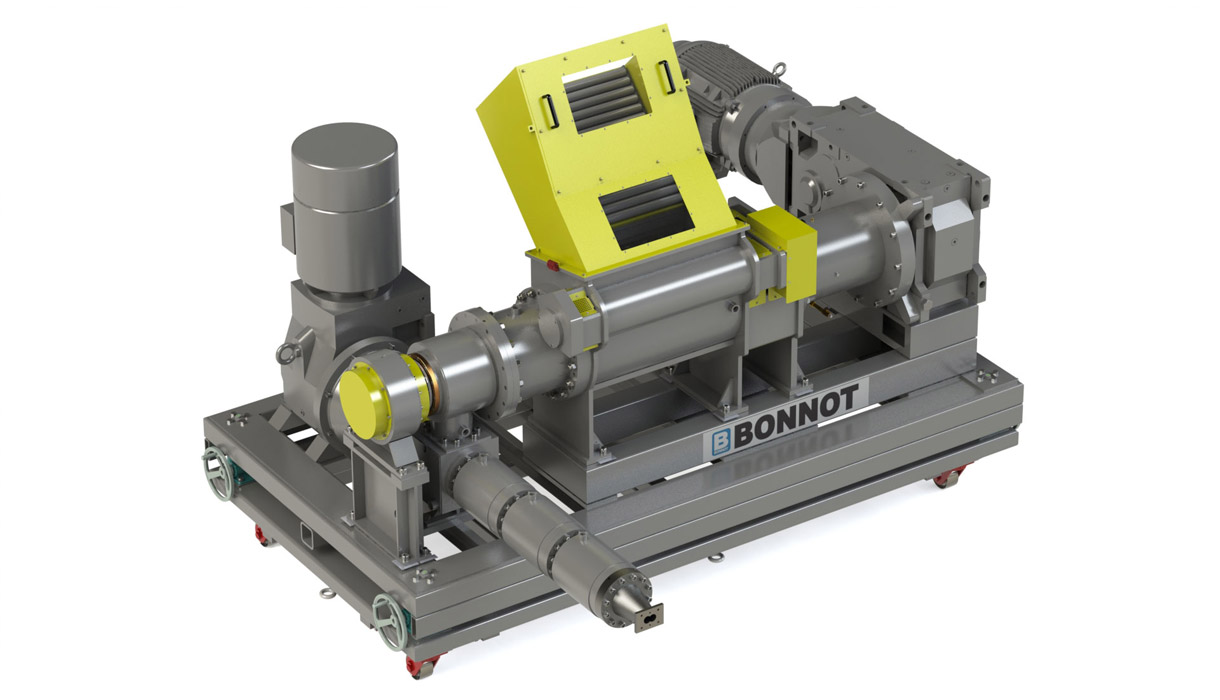

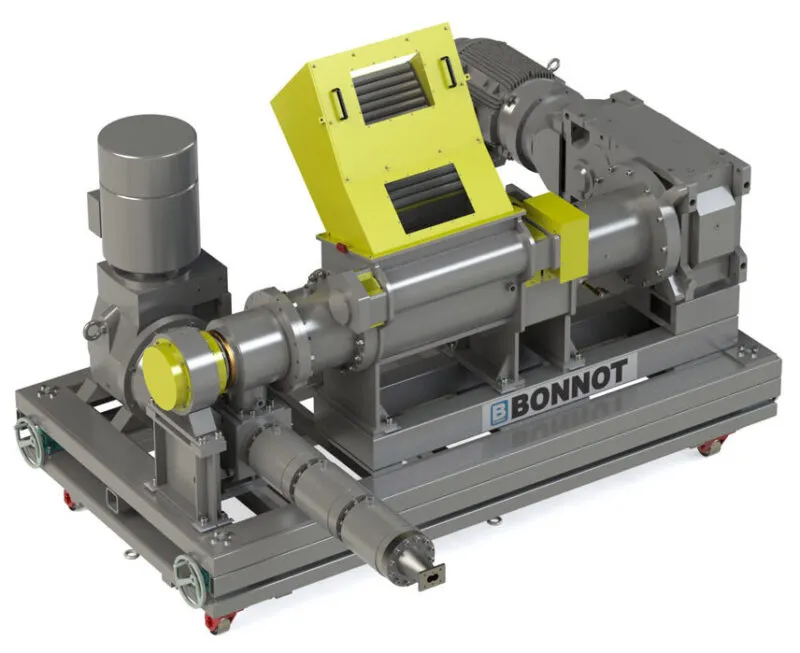

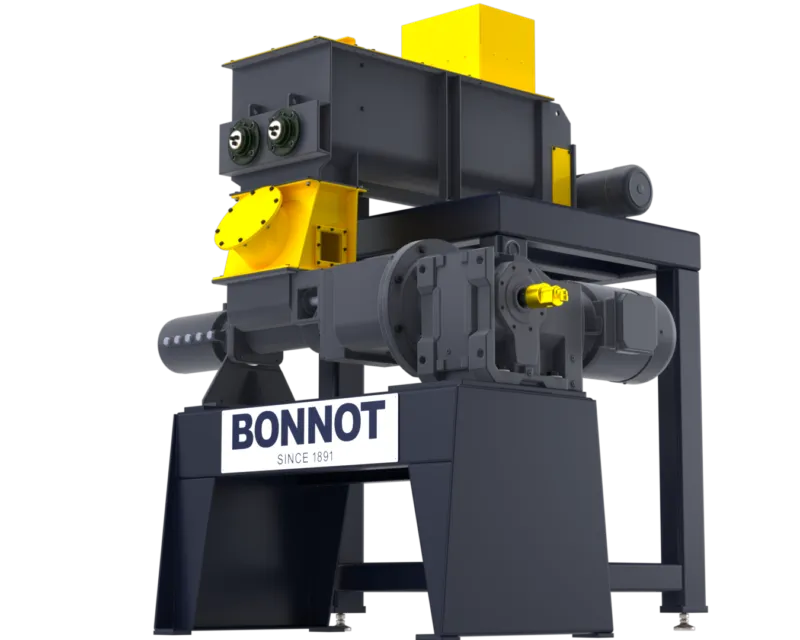

Throughout our rich history, Bonnot has adhered to a ‘rugged’ design philosophy in the development of our extruders. We prioritize simplicity, low maintenance, and long-life designs, earning the loyalty of numerous customers worldwide.

Extruders play a pivotal role in shaping various materials, resulting in a wide array of usable products. For instance, our food extruders contribute to the creation of breakfast cereals and pre-formed snacks, ensuring uniformity and quality through controlled pressure and temperature. Similarly, our food forming extruders are instrumental in crafting pet food and treats, maintaining consistency and quality for our beloved furry companions. These extruders can be employed independently or in conjunction with cooking extruders for unitized cooking and cooling processes.

In diverse industries, catalyst extruder machines find application in producing catalysts like high aluminas, gels, kaolin carriers, molecular sieves, and more. Bonnot offers extruders tailored to meet specific needs, whether it’s for producing minute pellets, solid rods, unsupported rings, or other catalyst configurations.

Rubber extruders from The Bonnot Company serve multiple purposes, including the creation of extruded hydrogels. These hydrogels are utilized in the manufacture of items ranging from contact lenses to replacement cartilage. Our rubber extruders excel at breaking down large, tacky rubber bales without the need for talc or special chemicals.

Extrusion equipment extends its reach to essential components for home purification systems. Originally employed in the clay industry for de-airing products, vacuum extruders are now utilized to create activated carbon. This process enhances the carbon’s adsorptive properties, preparing it for use in various air and water purification applications. At Bonnot, our expertise spans a wide range of base materials beyond activated carbon, and our test facility stands ready to demonstrate how extrusion can work for you.

Throughout our rich history, Bonnot has adhered to a ‘rugged’ design philosophy in the development of our extruders. We prioritize simplicity, low maintenance, and long-life designs, earning the loyalty of numerous customers worldwide.

Extruders play a pivotal role in shaping various materials, resulting in a wide array of usable products. For instance, our food extruders contribute to the creation of breakfast cereals and pre-formed snacks, ensuring uniformity and quality through controlled pressure and temperature. Similarly, our food forming extruders are instrumental in crafting pet food and treats, maintaining consistency and quality for our beloved furry companions. These extruders can be employed independently or in conjunction with cooking extruders for unitized cooking and cooling processes.

In diverse industries, catalyst extruder machines find application in producing catalysts like high aluminas, gels, kaolin carriers, molecular sieves, and more. Bonnot offers extruders tailored to meet specific needs, whether it’s for producing minute pellets, solid rods, unsupported rings, or other catalyst configurations.

Rubber extruders from The Bonnot Company serve multiple purposes, including the creation of extruded hydrogels. These hydrogels are utilized in the manufacture of items ranging from contact lenses to replacement cartilage. Our rubber extruders excel at breaking down large, tacky rubber bales without the need for talc or special chemicals.

Extrusion equipment extends its reach to essential components for home purification systems. Originally employed in the clay industry for de-airing products, vacuum extruders are now utilized to create activated carbon. This process enhances the carbon’s adsorptive properties, preparing it for use in various air and water purification applications. At Bonnot, our expertise spans a wide range of base materials beyond activated carbon, and our test facility stands ready to demonstrate how extrusion can work for you.