Extruder Design Features

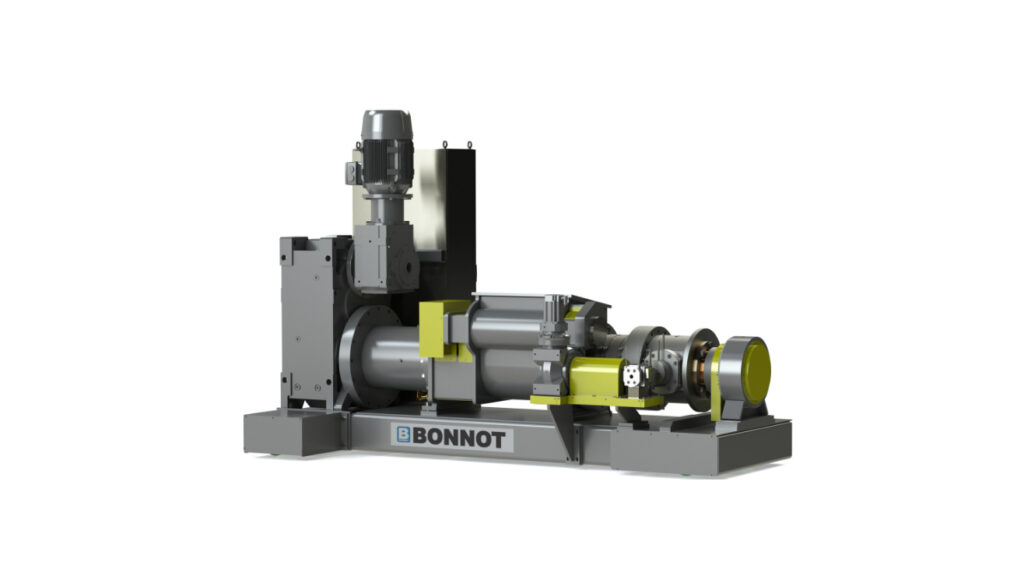

+ Custom feed sections to accommodate your batch size

+ Packer, Screw Geometry & Die Shape

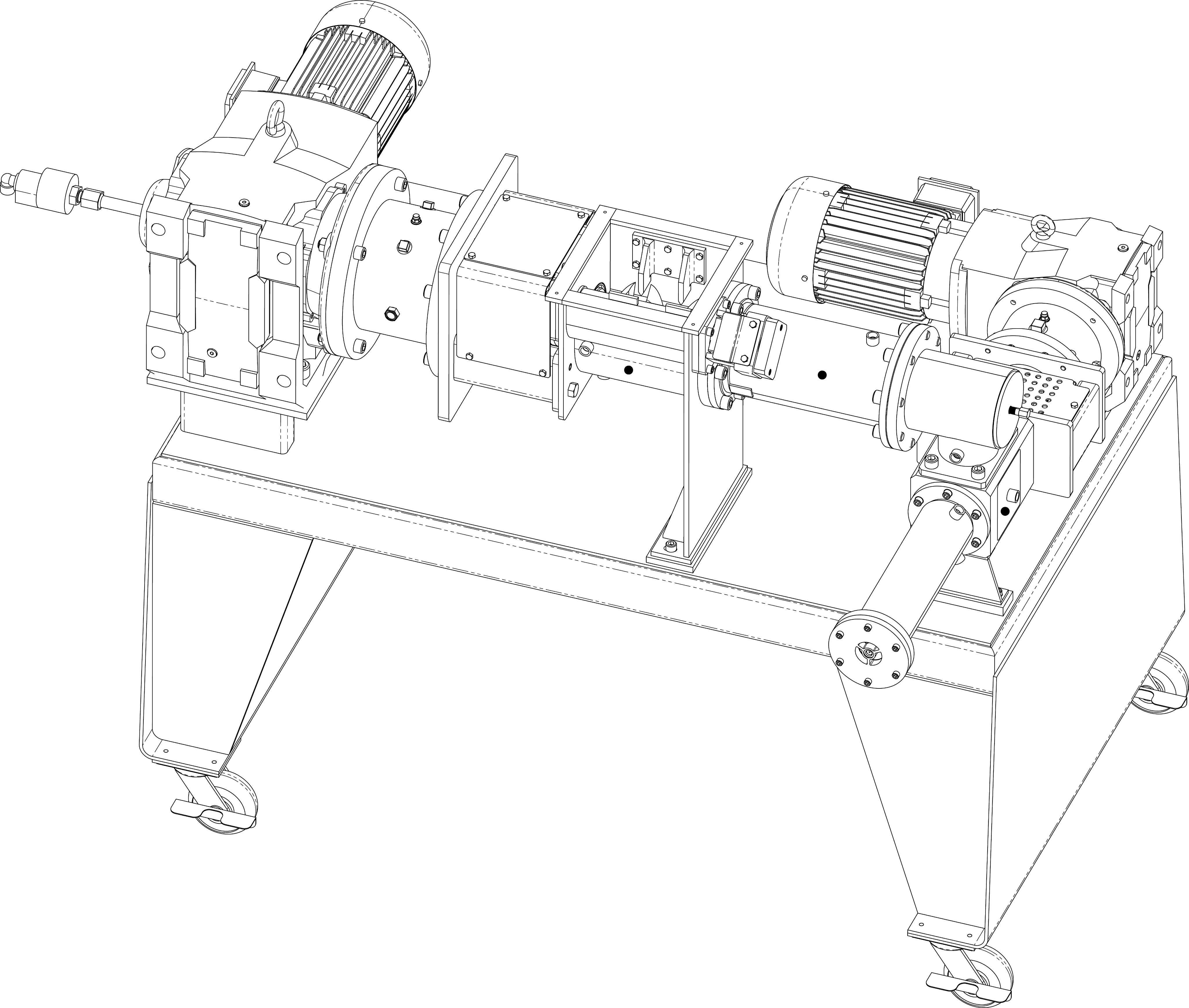

+ Custom contact component material selection to resist wear and corrosion

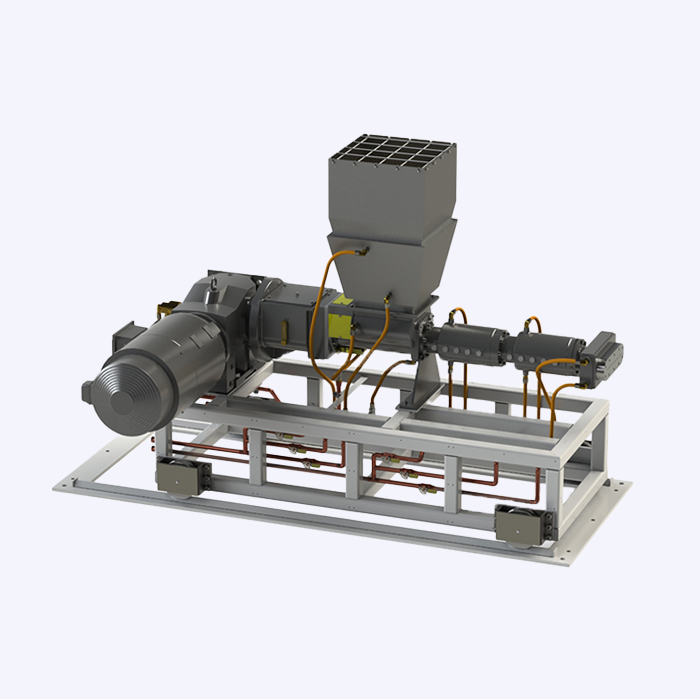

+ Temperate Control Manifold

+ Designs suitable for higher torque loads and to match the exact throughput you need

+ Custom bases to match centerline height with takeoff equipment or to add casters for mobility to fit your plant layout

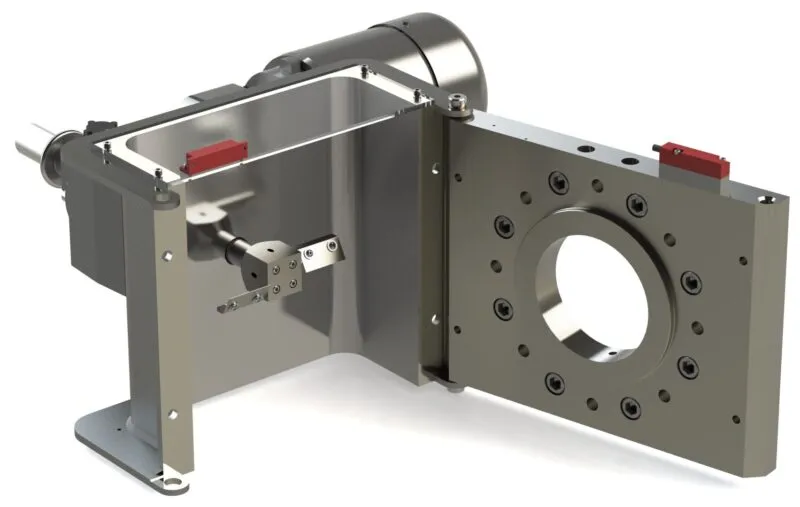

+ Custom designs for cleanability to aid with faster material changeovers

+ Custom dies to match the desired shape and size of your extrudate