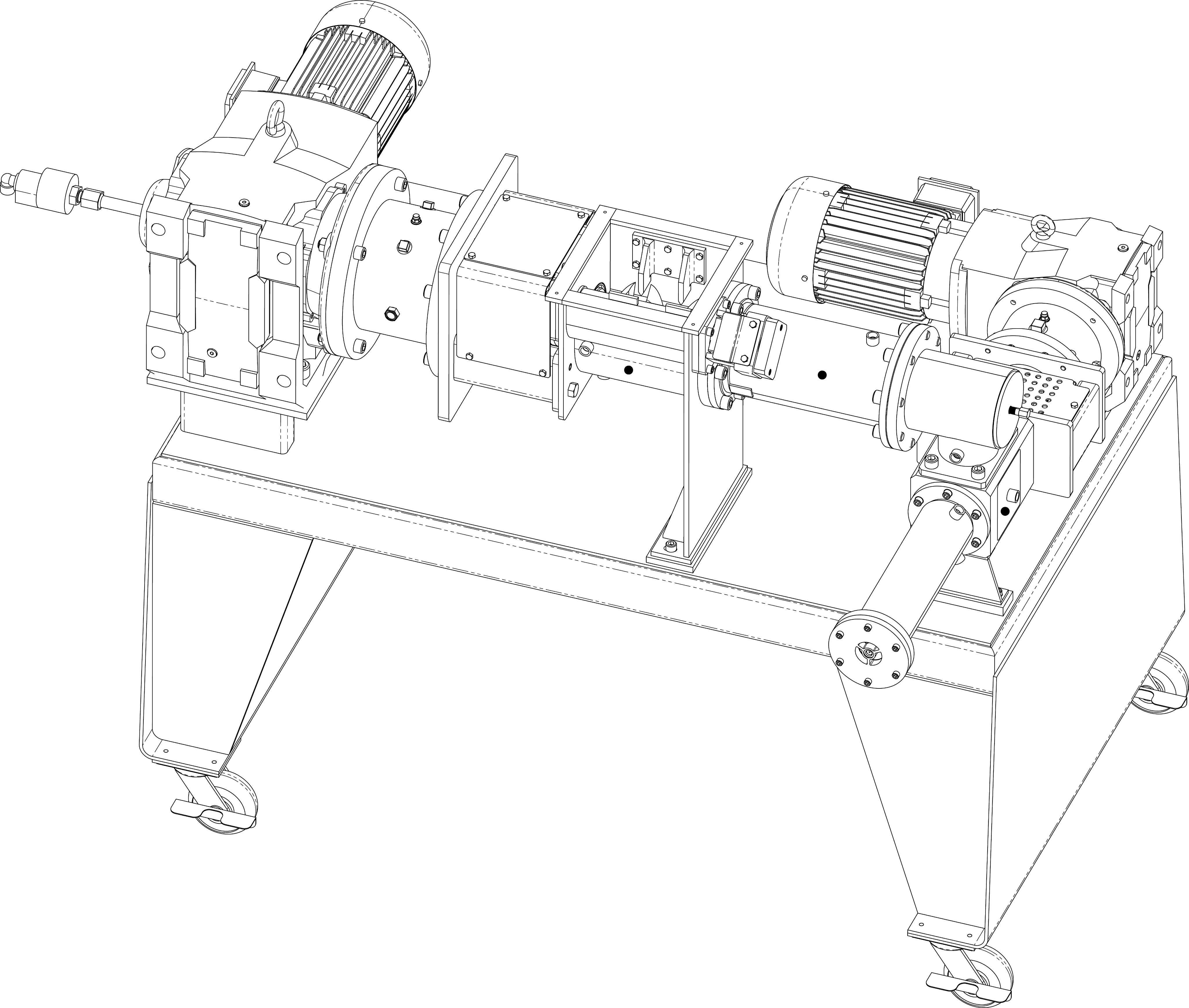

Extruder Design Features

+ High volume cost effective, robust designs

+ Temperature control

+ Customizable layouts and centerlines

+ Customizable feed area sizing

+ Batch loading options available

+ Gear Motor HP and speeds customized to each installation

+ Bench-top models available for smaller outputs