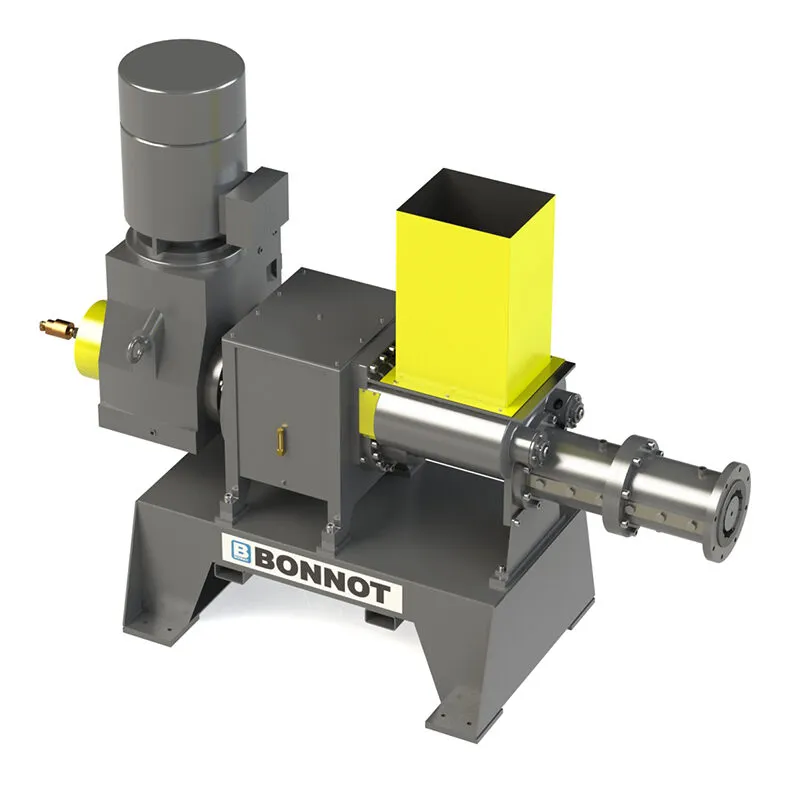

Extruder Design Features

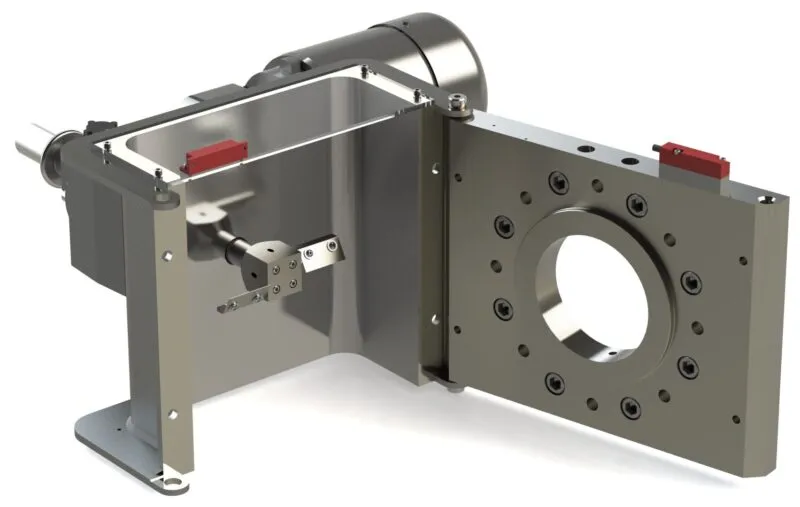

+ Jacketed barrel(s) for temperature processing control

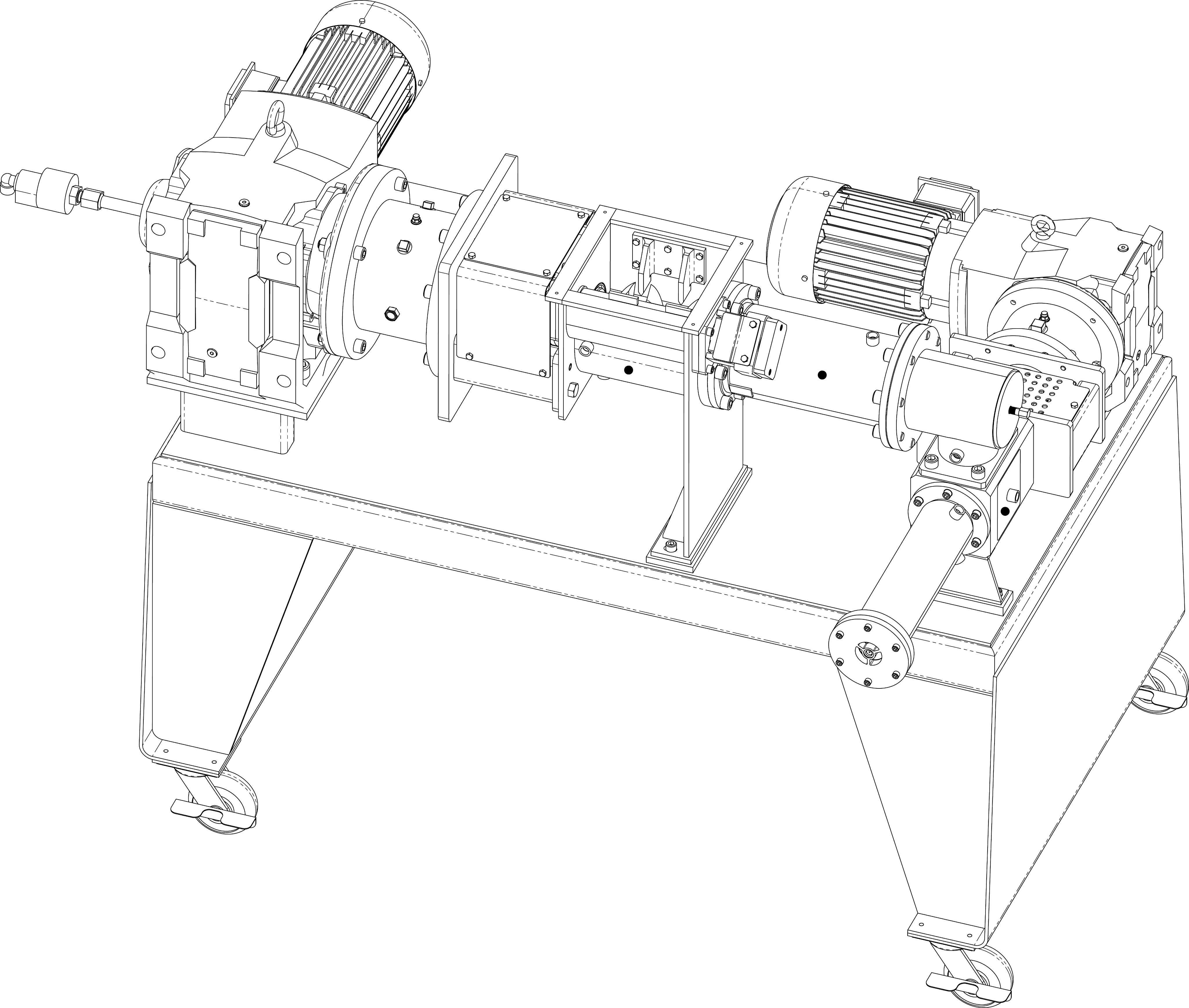

+ Various screw geometries available

+ The length-to-diameter {L/D} ratio can be changed to optimize the process

+ Hollow screw with rotary union for temperature control available on sizes 4" and above

+ Many die options available including multi-hole, single orifice and co-extrusion