Control Design Options

+ Designed and Built to Customer Specification

+ Configured with Industry Leading Commercial Components

+ Tested for Compliance with CE, UL, NEMA and Many More

The Bonnot Company Offers a Full Range of Control Options For Our Extrusion Systems

+ Designed and Built to Customer Specification

+ Configured with Industry Leading Commercial Components

+ Tested for Compliance with CE, UL, NEMA and Many More

Here is a fully integrated system offering 5 zone temperature control, pressure and temperature monitoring in a wash down enclosure.

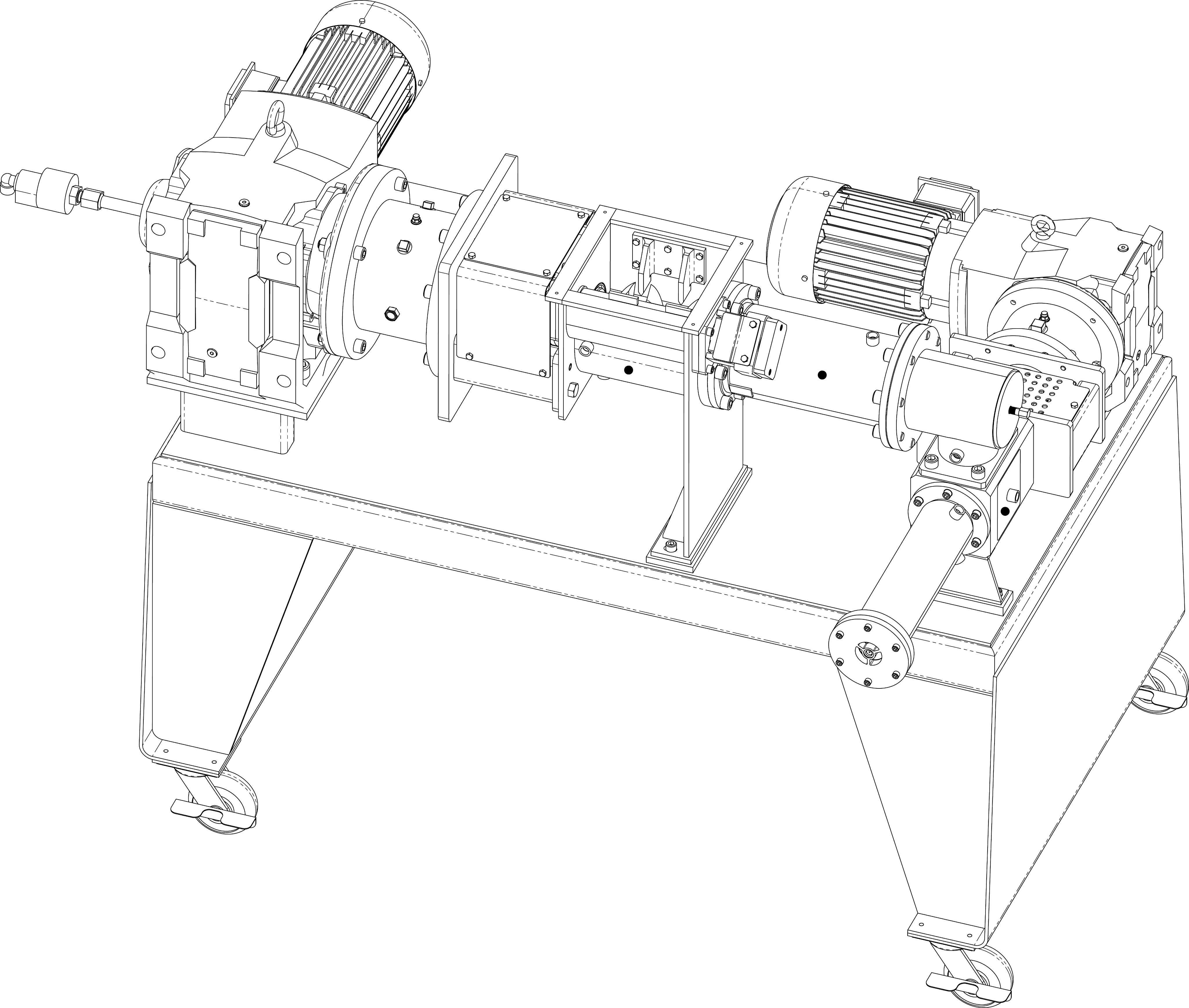

Fully integrated extrusion system incorporating a PLC control with operator station. Integration includes temperature control units, screen changer and die.

Our laboratory extruder comes with a standard offering PLC touchscreen controls for temperature & pressure monitoring and data capture & export.

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.

Get in touch with us