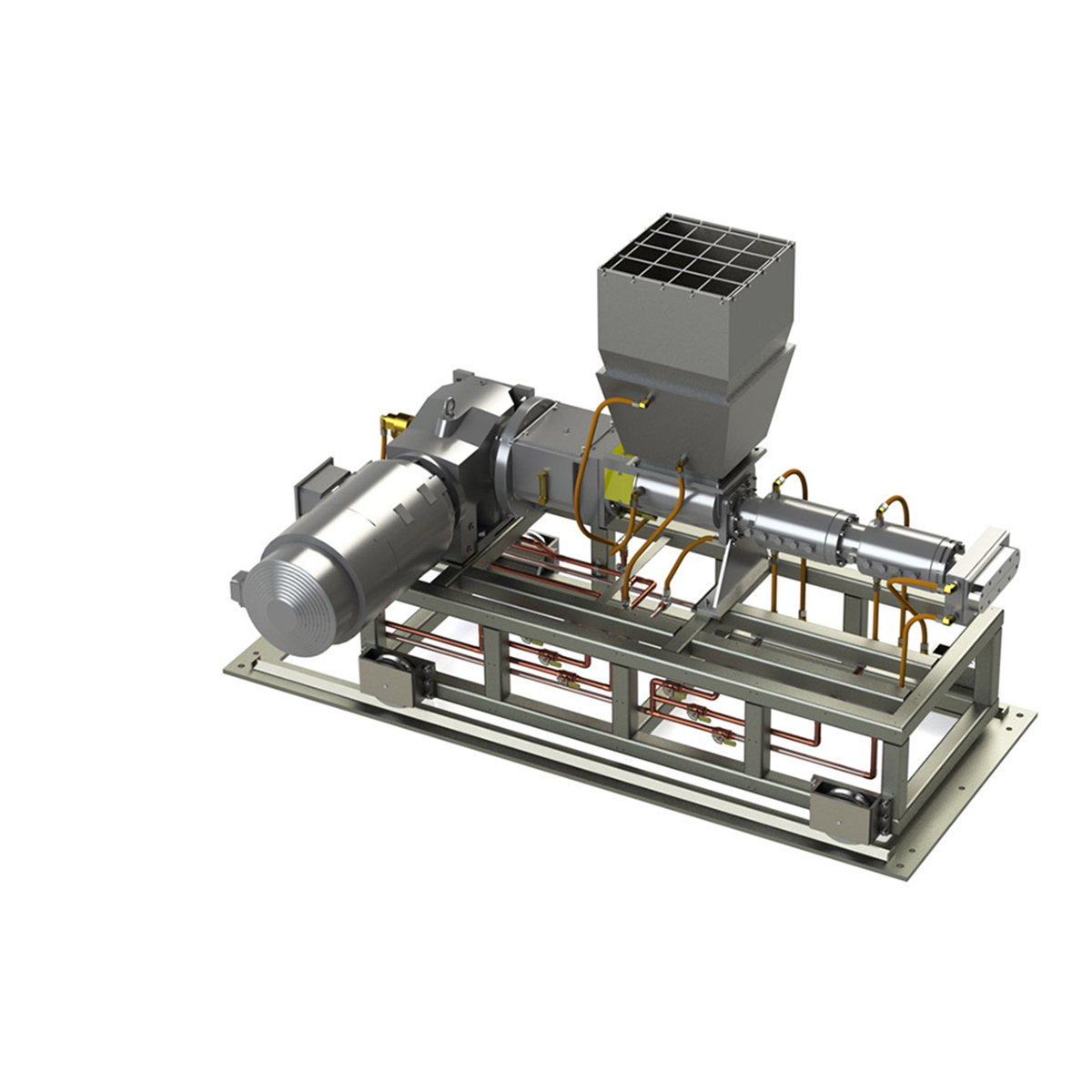

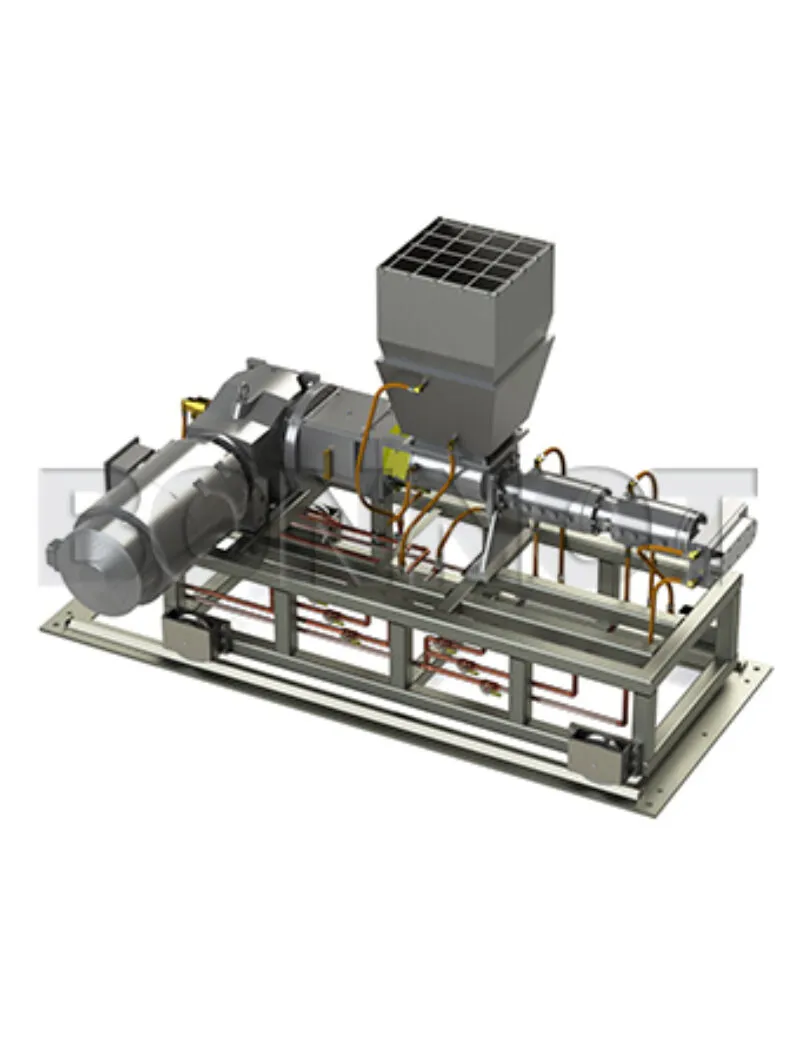

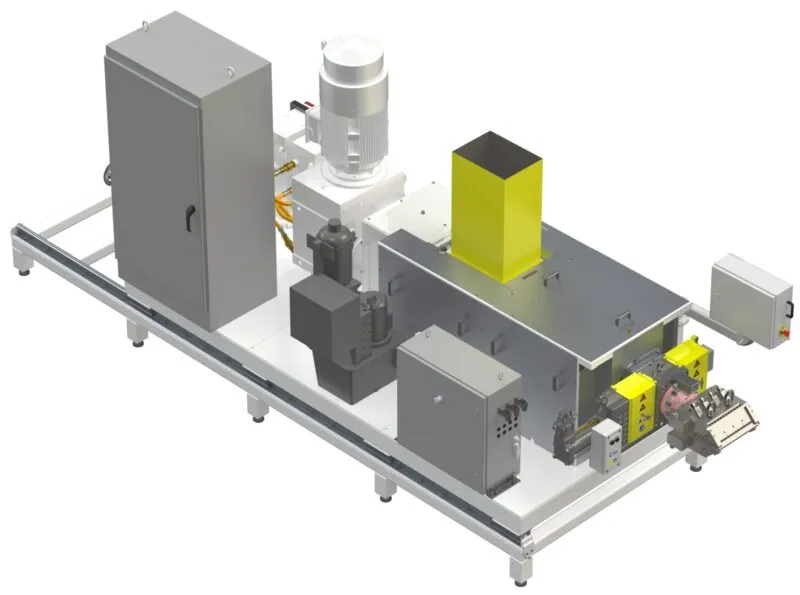

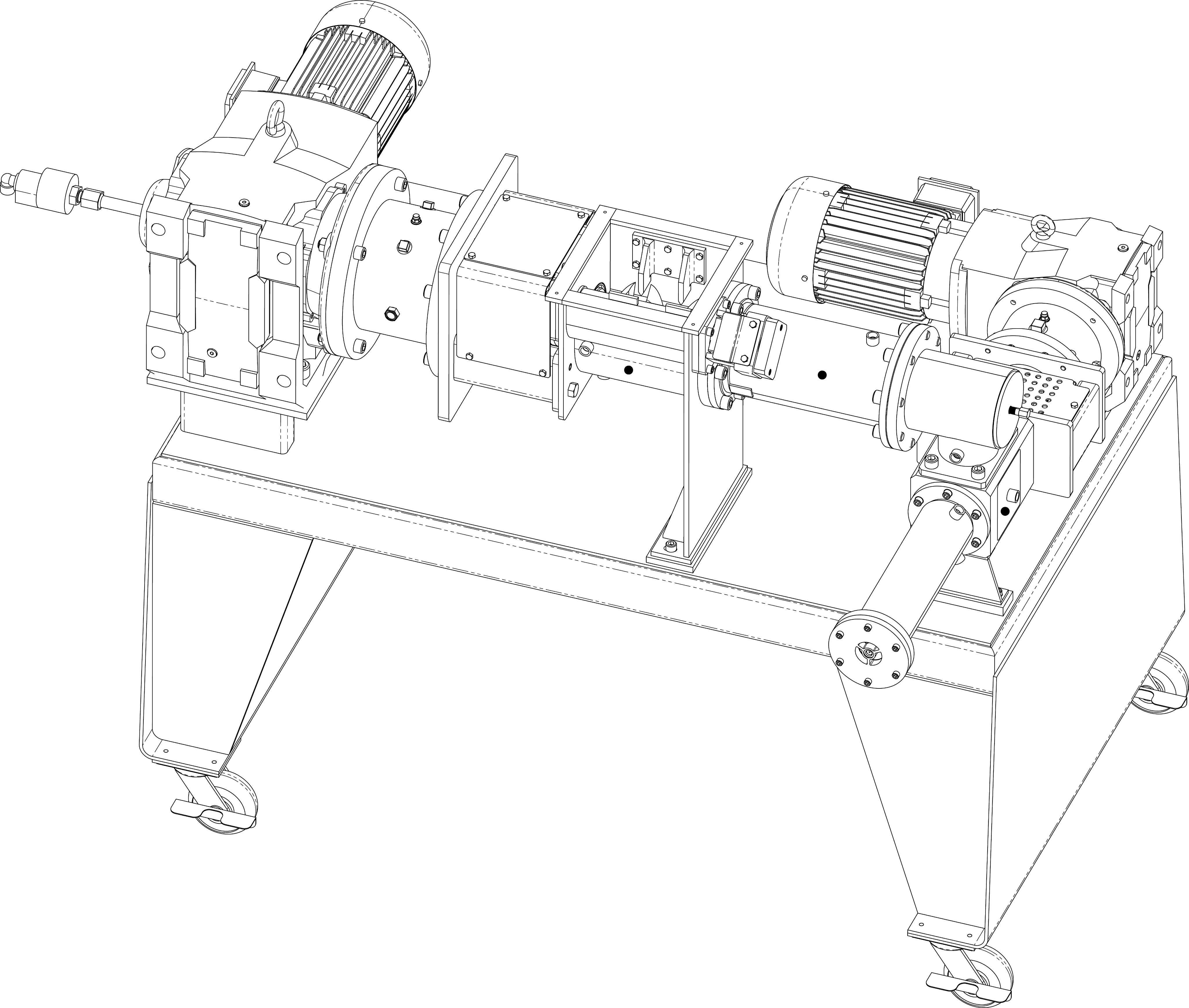

Extruder Design Features

+ Turnkey systems including CE

+ Screenchangers, Plumbing manifolds & dies available

+ Processing control with multiple temperature zones

+ Long life bushings & seals

+ Customizable dimensions

+ Medical grade stainless steel construction