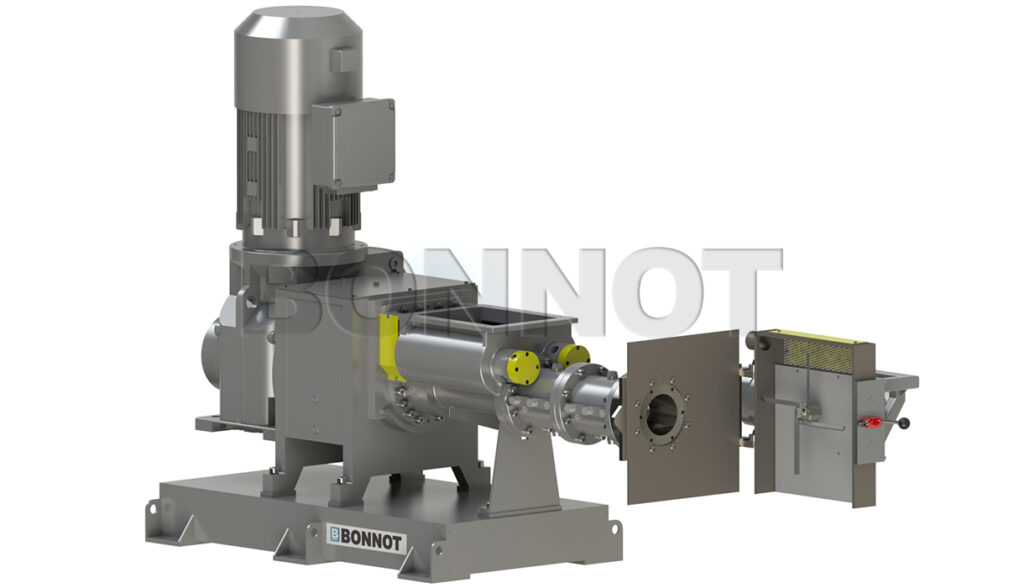

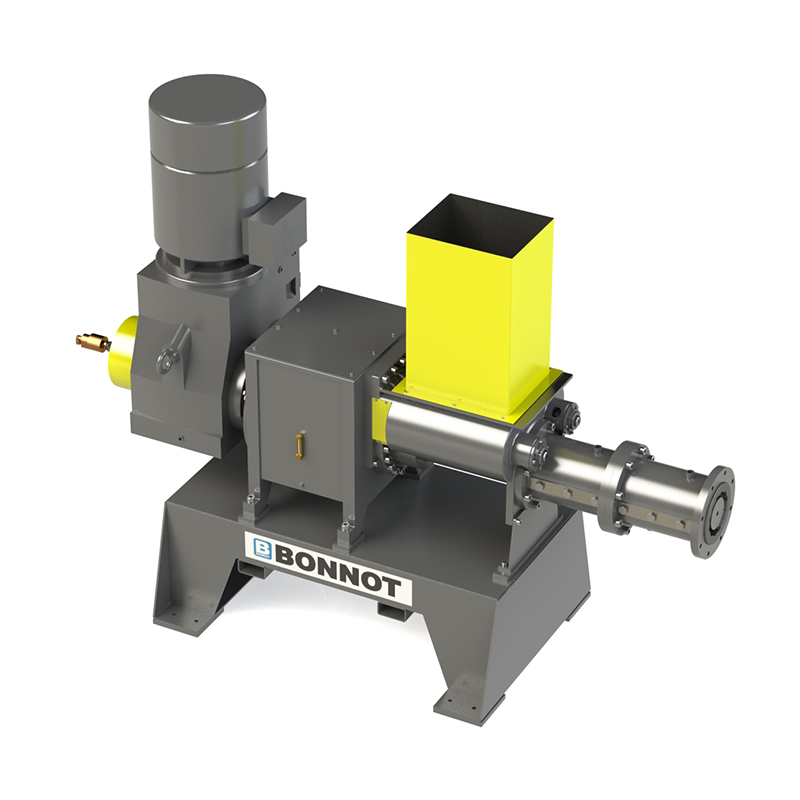

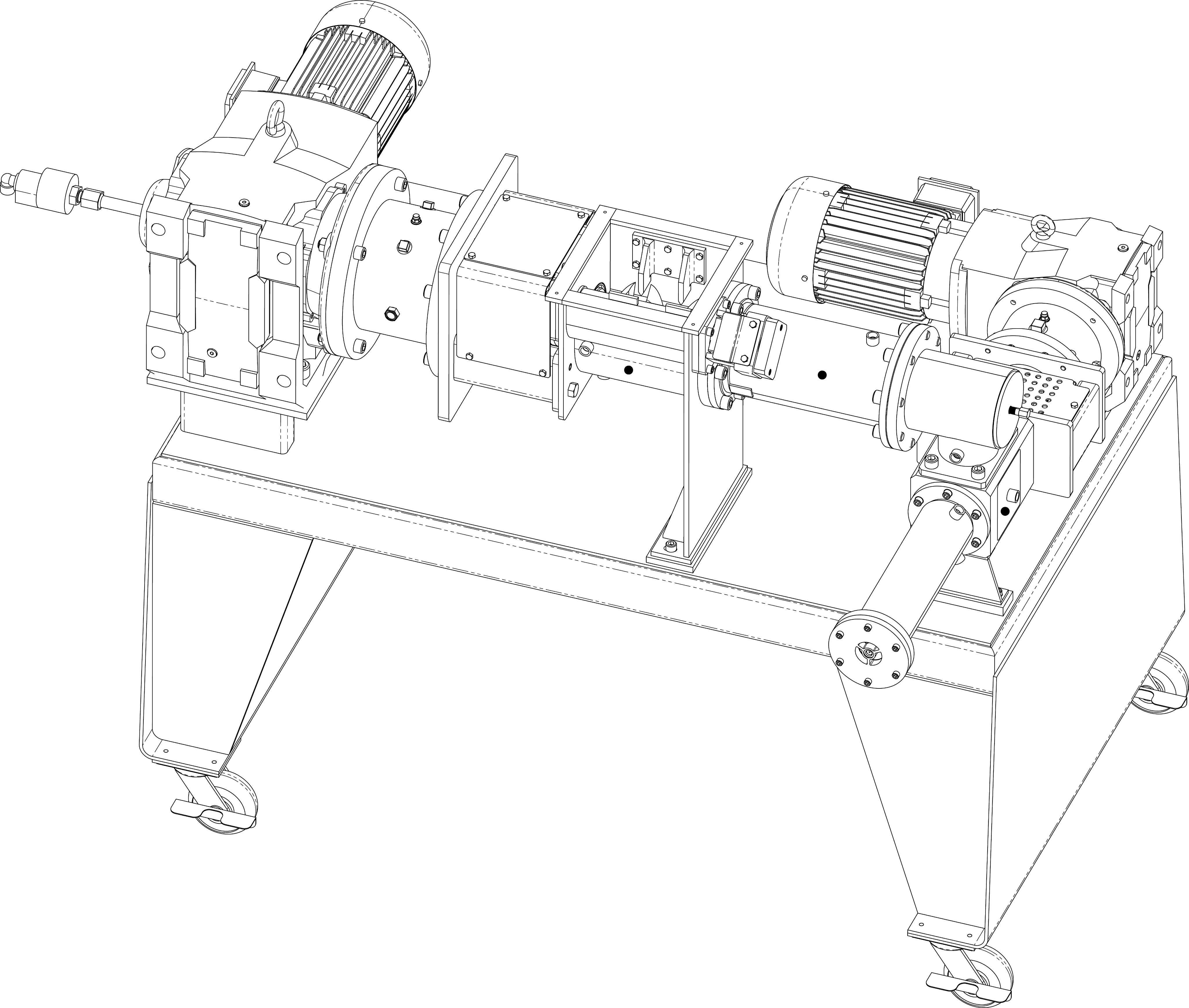

Extruder Design Features

+ Twin Packers for easy material ingestion

+ Hard surfacing and replaceable wear resistant barrel liners

+ Jacketed barrel for temperature processing control

+ Customizable dimensions & configurations

We have a long history of processing activated carbon, biochar and other carbon products

+ Twin Packers for easy material ingestion

+ Hard surfacing and replaceable wear resistant barrel liners

+ Jacketed barrel for temperature processing control

+ Customizable dimensions & configurations

Specifications

Testing on our CB 2 Series extruder in our test facility.

Our extruders are used to process a range of activated, char and bio char carbons.

Intensive mixing is often required for carbon applications. In our test room we have access to a number of different mix styles for trials.

Here are some samples of extruded carbon pellets. We are able to form logs, hollow profiles and pellets.

The Bonnot Company is vertically integrated and able to fulfill large orders. Here is an order for (4) 6 Series (6″) Extruders ready for shipment to a customer facility.

We ofter a range of material handling and feeding equipment. Depicted here is our Twin Shaft Feeder mounted over out 4 Series (4″) Carbon extruder.

The Bonnot Company offers cutters for certain applications, including carbon. Depicted here is our 6″ rotary die face cutter, used for cutting carbon and activated carbon pellets.

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.

Get in touch with us