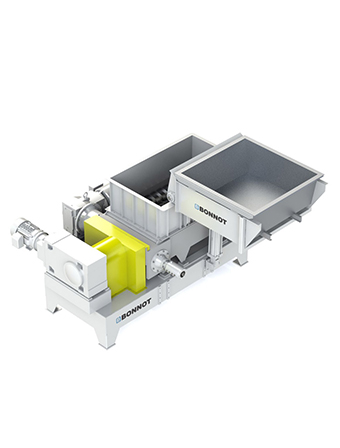

Custom Extruders, Cutters & Feeders

The Bonnot Company can provide custom extrusion, feeding, and material cutting equipment as well as custom dies for a host of applications

One of the things that has set The Bonnot Company apart in the last 125+ years, is our openness and willingness to customize to a customer specification or application. We can create custom extrusion equipment to fit your needs. Our extrusion equipment can be used for many different applications from rubber to chemical catalyst, to food and pet food applications and more. Bonnot can design our equipment to optimize your processing requirements

Customization options: Feed section, barrel ID, materials of construction, controls, drive type and orientation, machinery bases, etc.

Extruder Design Features

- Custom feed sections to accommodate your batch size

- Custom hopper chutes and batch loaders to aid in feeding material into the hopper

- Special packer designs to help ingest different types of materials

- Custom bases to match centerline height with takeoff equipment or to add casters for mobility to fit your plant layout

- Custom contact component material selection to resist wear and corrosion

- Designs suitable for higher torque loads and to match the exact throughput you need

- Custom designs for cleanability to aid with faster material changeovers

- Custom dies to match the desired shape and size of your extrudate.

Want to Prove it Out?

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.